Customer Background

Customer is a leading producer of fine-blanking tools, precision parts for the automotive industry, and automation systems. They cover design and part production. Plant locations are in Europe, China, Japan, and the U.S., and are headquartered in Switzerland.

Challenge

The customer was seeking a seat pawl washer to remove fine-blanking oil from the production process. Seat pawls needed to have a visually clean appearance at a production rate of 28,000 pieces per hour. Seat pawls are a safety feature in automobile seatbelt systems. They make up the locking system for when a vehicle stops suddenly, such as in a collision. The pawl is on the upper end of a weighted pendulum and locks the ratcheting teeth when the pendulum swings due to forward inertia. The seat pawls measure approximately 1” diameter by 3-4 mm.

Solution

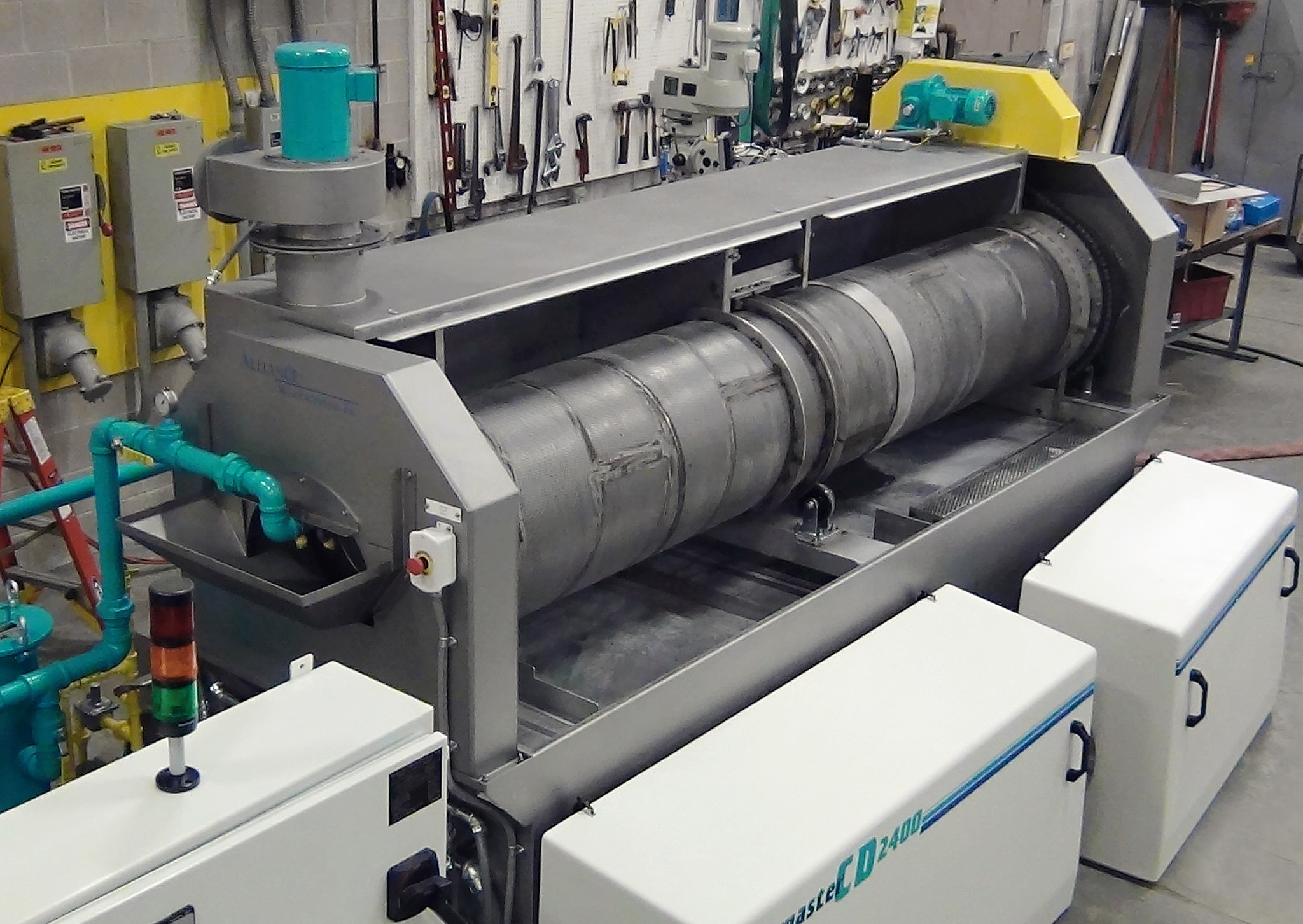

Alliance provided an Aquamaster CD-2400 rotary drum parts cleaning system with wash, rinse, and heated blowoff process zones. A rotary drum design was incorporated to convey parts using interior welded flights and kicker bars, with perforations throughout the entire length of the drum. Drum is supported on each end by idler rollers on the exterior of the machine. The drum is driven by a chain and has a jam sensor for automatic shutoff. Included were an exhaust fan system, dual filter micro filtration, and high-velocity air knives in the heated blowoff stage.