Alliance Manufacturing, Inc. is an industrial parts washer manufacturer and supplier of parts cleaning systems for use in a wide variety of industries.

Alliance Manufacturing, Inc., incorporated in 1994 in Fond du Lac, WI, is a manufacturer of large industrial parts washers and electronic component cleaning systems. We specialize in the conceptual design, engineering, and manufacturing of water-based (aqueous) industrial parts washers and vacuum degreaser cleaning systems for the industrial products market. Our engineers have developed a full line of industrial parts cleaning equipment systems, including belt, chain, monorail, front/top loading cabinet, indexing, return-to-operator, compact cell, rotary drum, oil removal equipment, and custom systems engineered for specific cleaning applications. Our parts cleaning machines are designed to meet the production and cleanliness requirements of our customers.

From small companies to multi-national corporations, we have manufactured industrial parts washers and cleaning equipment systems for a wide variety of customers across several industries. Our industrial parts washing machines are currently being used to clean components for OEM and Tier 1 suppliers in the automotive, agricultural, aviation, alternative energy, appliance, construction, defense, electronic, screw machine, heavy equipment, housewares, marine, mass transportation, small engine, medical, pharmaceutical, and other industries. The predominant market served is automotive. Alliance has supplied large industrial parts washing machines to U.S. manufacturers as well as several international companies.

Applications & Industries Served

Agriculture | Alternative Energy | Automotive | Aviation and Aerospace | Defense and Military | Electronics and Electrical | Firearms and Ammunition | Food and Beverage | General Manufacturing | Heavy Equipment and Construction | HVAC and Plumbing | Marine | Rail and Transit | Remanufacturing and Repair | Medical and Pharmaceutical | Small Engine | Tools and Measuring Devices

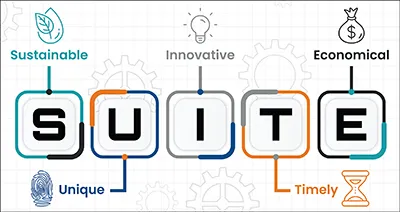

Why Choose Alliance?

Ease of Maintenance

- Complete access to all process zones

- Pull-out spray headers and removable nozzles

- Efficient water filtration

- Convenient tank accessibility

Quality

- Stainless steel fabrication and corrosion-resistant materials

- Brand-name components

- Energy efficient and environmentally friendly

- Aesthetically appealing

Flexibility

- Engineered per cleaning application

- Ability to meet customer electrical and mechanical specifications

- Easily interface with system integrators and automation devices

- Many optional accessories available

Experience

- Experts since 1994 with over 1000 machines sold

- Qualified staff utilizing latest technology

- In-house engineering, programming, and assembly

- Cleaning effectiveness tested and verified

Customer Satisfaction

- Numerous repeat customers

- Timely service

- Ergonomic and safe designs

- Focus on sustainability

- Attention to detail

Our Customers Say

“Alliance Manufacturing provides sound machines that meet all our expectations and perform great under our harsh working environment.”

“The Alliance machine does an excellent job of cleaning our parts. It saves time by reducing material handling and it delivers parts to the next operation. In addition, with the externally mounted filter chambers, we can filter the water to meet cleanliness requirements. By keeping the water cleaner, it extends the life of the wash solution and chromate bath.”

“It has been one month since we lowered the boiler and heat transfer pack to floor level. We are thrilled with how smoothly the machine is working. Heat up time and the quality of cleaning is excellent.”

“The washer is working quite well with the product we are washing, we hardly use any of the detergent. It seems that if we control the temp, the water itself gets the parts nice and clean.”