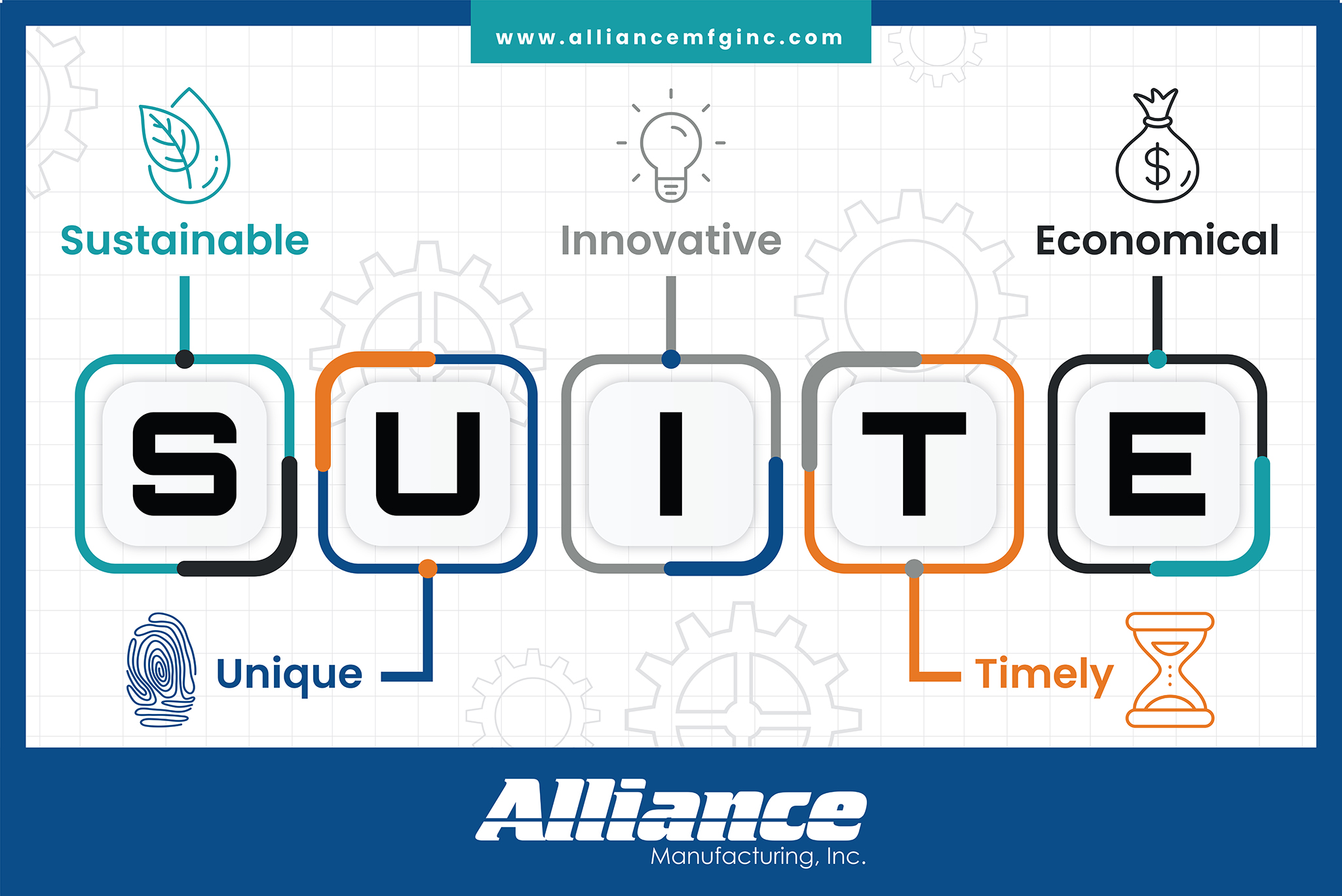

President’s SUITE Update

2021 3rd Quarter Recap

Ken Manninen, President

Products

(1) Cleaning system for left and right sub-frame aluminum castings (Machine #964)

(2) Cleaning cast iron brake calipers on specific part fixtures (Machine #1014)

(3) Fixture holding plastic packaging rails (Machine #948)

(4) Cleaning system for lower engine blocks (Machine #1022)

Processes

Aftermarket support of our machines has been very high on our priority list for the past year. We have been working to find ways to improve our customer’s experience on procuring service parts and replacement items. With interruptions in the supply chain, we have been expanding our supply base and gearing up to help customers in need. We are trying to find ways to better educate our customers on items that they will likely need to keep on the shelf to minimize or prevent downtime. If things do not loosen up in the supply chain, we will be ready to help source alternatives or work arounds to keep our customers machines in operation.

People

I want to send a special welcome to the most recent additions to the Alliance team; Mistie, Alan, Jesus, and Drew:

Mistie Smith, Receptionist/Accounting Assistant

Mistie relocated to Wisconsin approximately 4 years ago from Akron, OH. She enjoys spending time with family, reading, and projects that allow her to organize and get creative.

Alan Tenhaken, Mechanical Engineer

Alan earned a BS in Mechanical Engineering from UW-Milwaukee. While not at work, Alan enjoys riding his motorcycle, getting techy with a little gaming time, or playing live sports (off screen).

Jesus Roque, Field Service Technician

Jesus has a broad knowledge in field service and machine repair. He has traveled extensively throughout his career. He enjoys spending time with family, fishing, and camping. One of his favorite activities is cooking authentic Puerto Rican cuisine.

Drew Lasher, Mechanical Assembler

Drew comes to us from a major corrugated box manufacturer where he maintained and repaired very large machines. He was formerly trained as an auto mechanic and is very hands-on and loves building things. Drew enjoys time with his family, hunting, fishing, and training his dog.

SUITE Employee Award – The SUITE award is an open vote process by our peers, to quarterly recognize an individual within the company that has gone above and beyond for their co-workers. This quarter’s SUITE award goes to…

Dale Popp, Mechanical Assembler

- Dale has a can-do attitude and is a hard worker every day.

- He is a dedicated company person and talks very highly about the company.

- Dale is very knowledgeable on machine builds and is a great problem solver.

- Even though mistakes are made by others, he jumps in to fix it without a complaint.