Customer Background

A leading global manufacturer of pistons for both gasoline and diesel engines for use in the automotive, agricultural, industrial, recreational, marine, and heavy equipment industries. They are based out of Wisconsin, and are a joint venture of two companies in Germany and Japan. U.S. plants are located in Wisconsin and Indiana. There are also plants located in Germany, Japan, Mexico, Brazil, France, China, India, and the Czech Republic. Pistons are made from various aluminum alloys, which are melted in the company’s foundry. The company houses the entire machining and finishing operations for their products.

Challenge

The customer was in need of a parts washer to remove loose burrs on drill holes, and chips in lock rings and ring grooves for two different types of aluminum pistons. The pistons had diameters of 70 mm to 105 mm x heights of 50 mm to 110 mm. Parts needed to be visually clean, but residual moisture was acceptable. The pistons needed to be kept at ambient temperature and exit free of coolant residue. Alliance needed to meet a 16 to 32 second cleaning cycle time per piston.

Solution

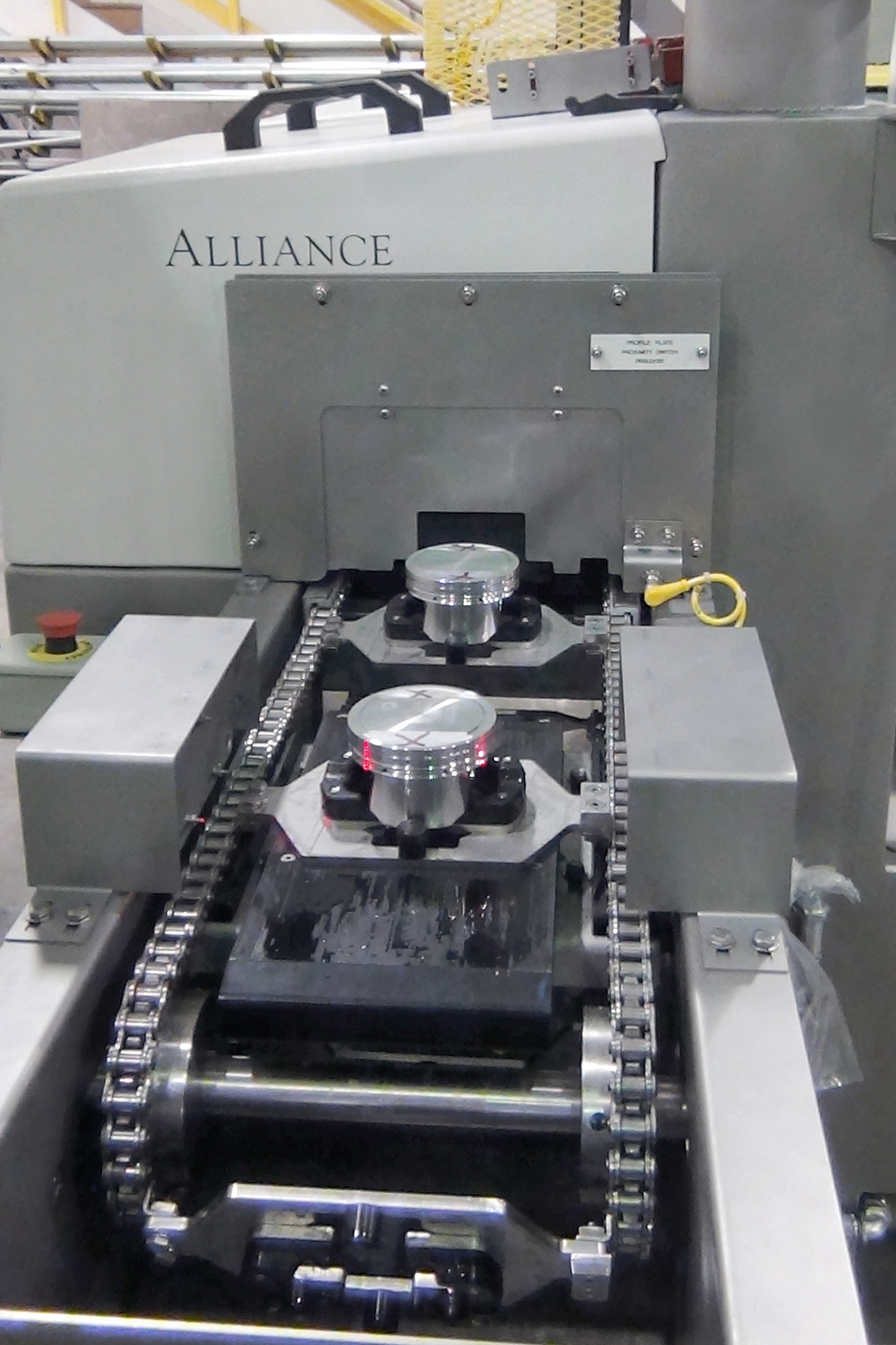

Alliance provided an Aquamaster CC-1200E indexing piston washing system with high- and low-pressure wash and regenerative blowoff modules. Pistons will travel on the conveyor via stainless steel chains with part fixture that are capable of rotating in a single position in the wash for cleaning ring grooves. A probing device for cleaning locking ring grooves and a locating device for spraying drill holes are part of the indexing operation. Sensors located at the ends of the machine stop the parts to load and unload by another machine. A recirculating chiller is added to chill the wash solution. A mist collection/exhaust system, belt-type oil skimmer, interior lighting and viewing windows in the wash zone, insulation, and a sound-dampening package were included options.