Customer Background

The customer is a leader in automotive safety, producing advanced active systems in braking, steering, and suspension. In addition, they develop and manufacture sophisticated occupant safety systems including airbags, seat belts, and steering wheels. The company has over 60,000 employees working in more than 185 locations in every vehicle-producing region worldwide.

Challenge

The customer required a cell-style cleaning system for demagnetizing and removing coolant and chips from an input shaft for electronic vehicle steering. Parts were to be manually loaded and unloaded from a single operator station. Mistake-proof loading of one (1) part every 30 seconds was essential. The prime objective was to eliminate any potential contamination, primarily magnetic particles.

Solution

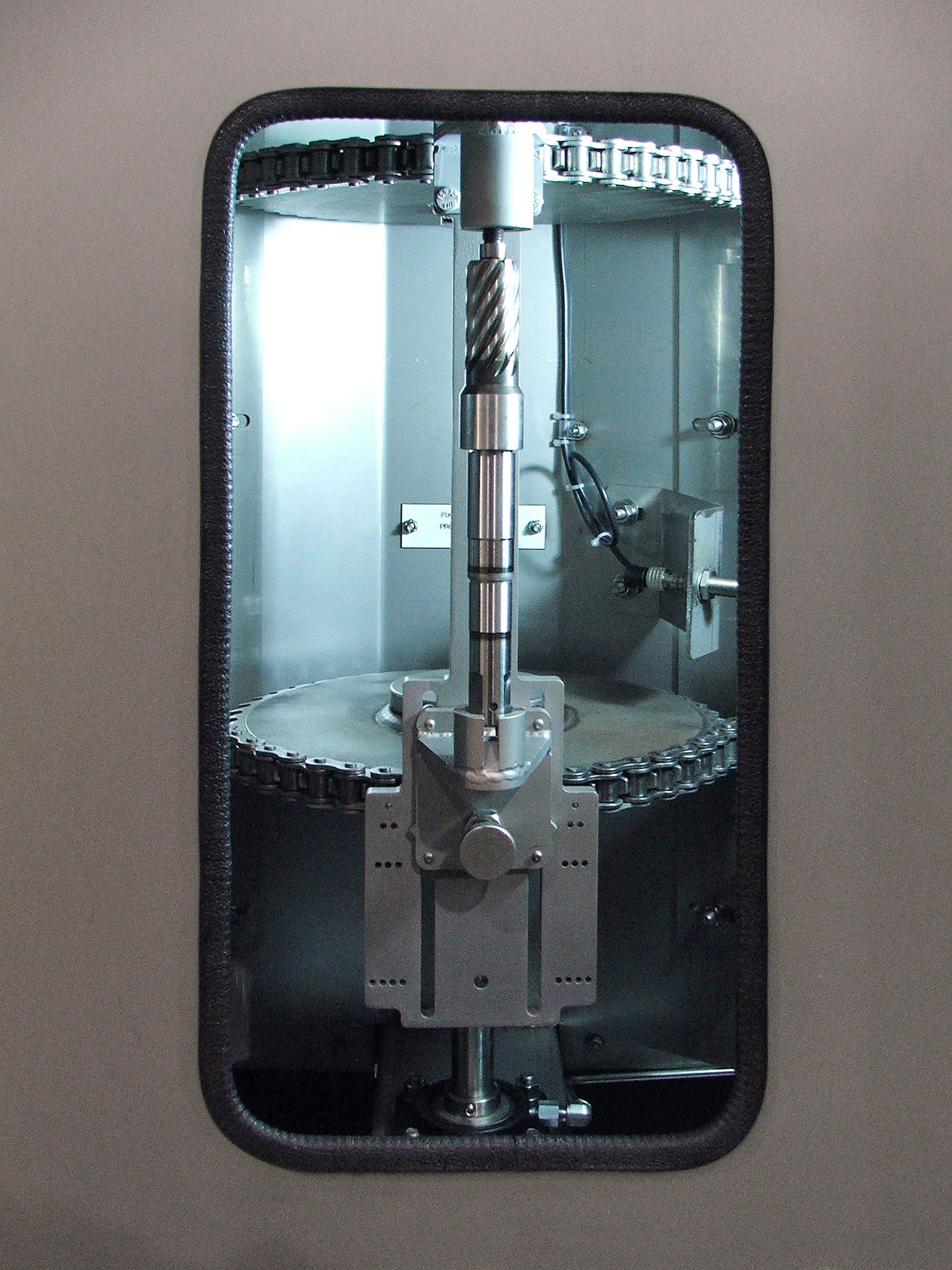

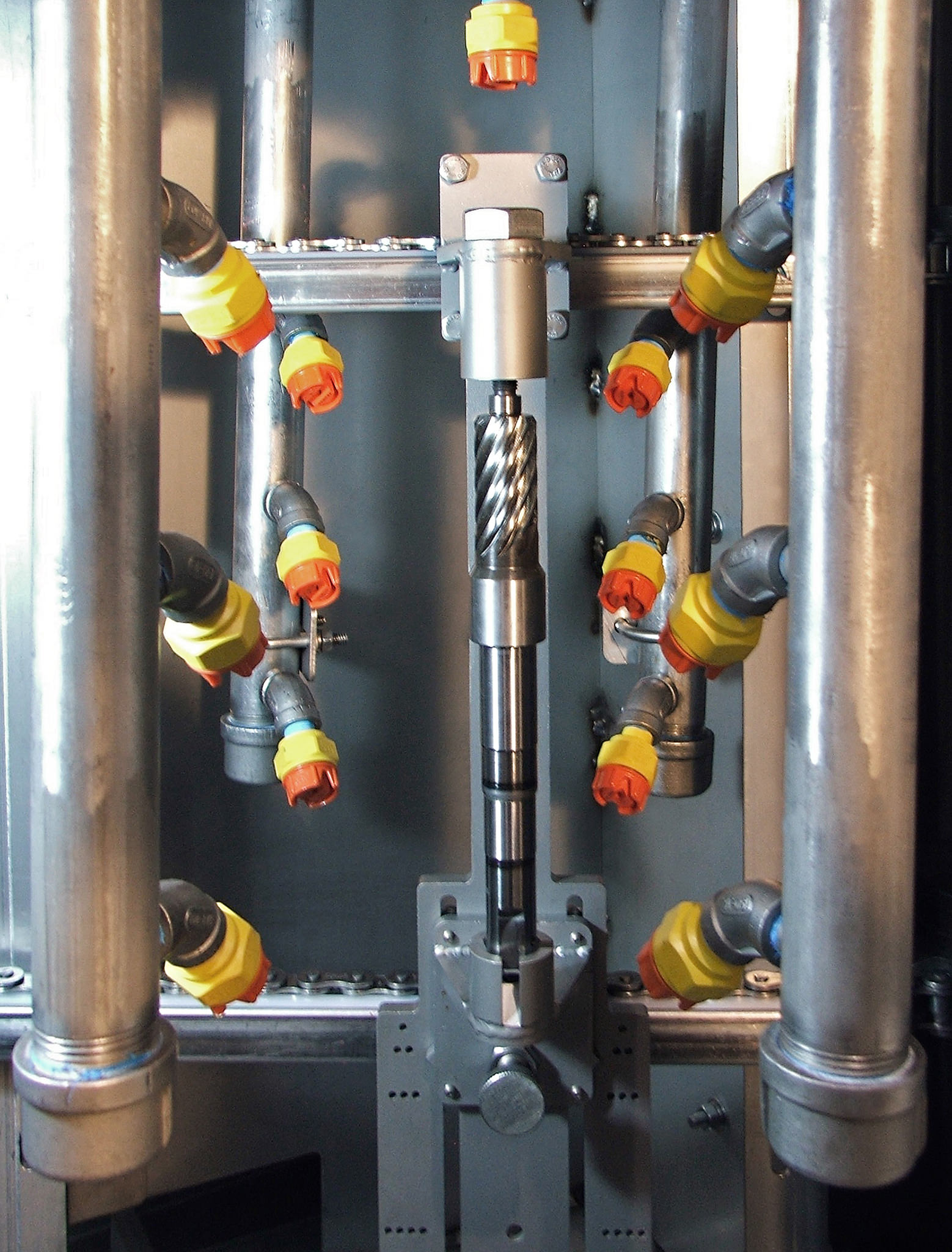

Alliance provided the customer with an Aquamaster CC-600 rotary indexing parts cleaning system. The machine was designed with a tight footprint to accommodate a single operator load/unload position. A direct-drive gearmotor with a clutch brake system powers the indexing conveyor, which holds three custom-designed part fixtures. The part fixture is adjustable can accommodate a variety of part styles. Prior to entering the wash zone, parts pass through a watertight, potted-coil surface demagnetizer. Soiled parts are loaded onto the machine, demagnetized, washed, blown off, and are returned back to the load position.