Customer Background

One of the largest tier II stampers / assemblers in North America, with a manufacturing footprint allowing for full coverage of Canada, USA and Mexico.

Challenge

The customer needed to remove water soluble stamping lube from the stampings, while maintaining a very high production rate.

Solution

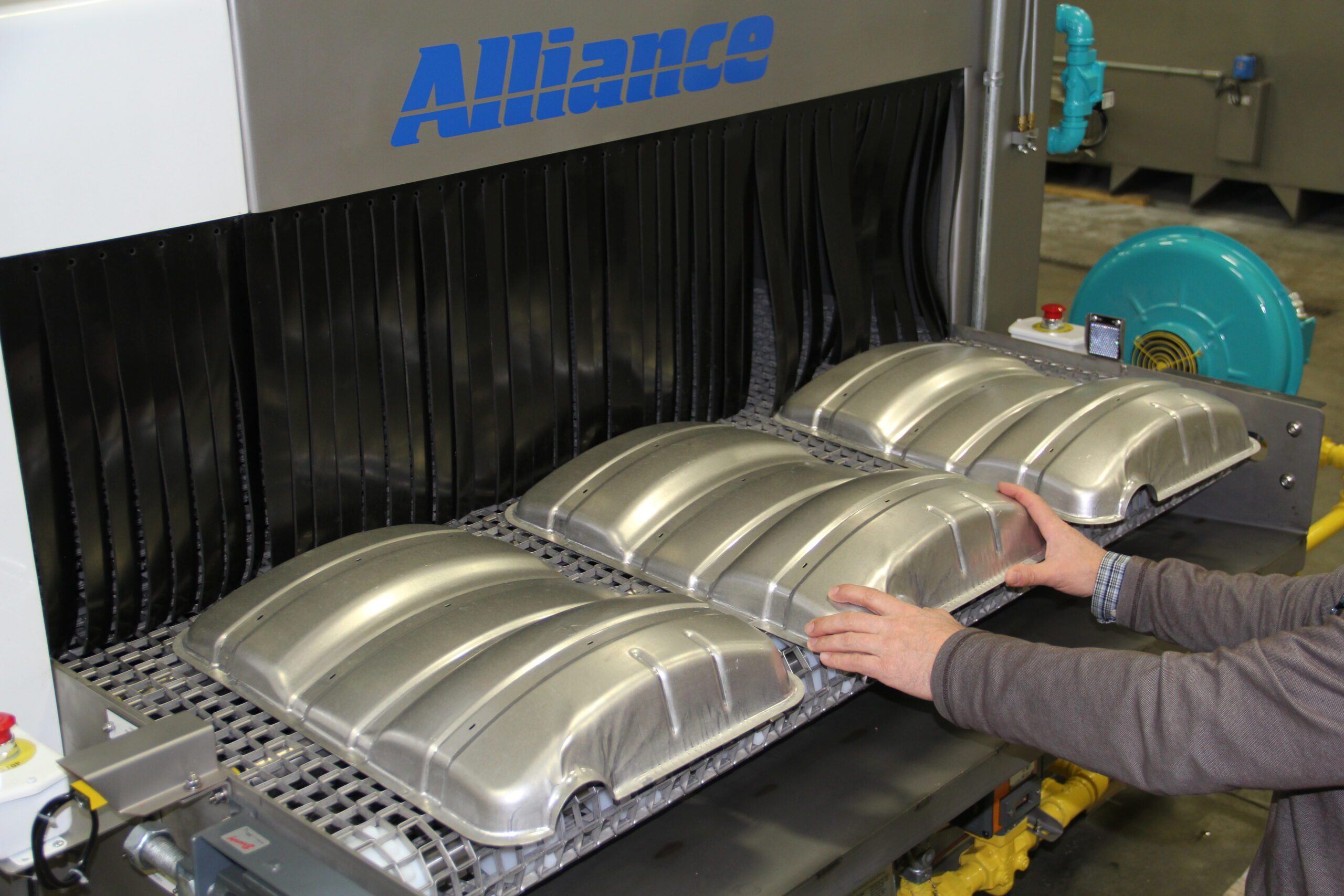

The Aquamaster CB-6000XE conveyorized belt washer was designed to wash and dry large stamped steel parts for a customer located in Tennessee. This washer was designed to process 5,400 parts per hour on the 60” wide conveyor belt. Due to the large GPM and CFM requirements, the washer utilized natural gas for heat. Slide-out spray manifolds were incorporated within the wash zone for ease of maintenance and serviceability.