Customer Background

Customer is a producer of high-tech automation systems, such as conveyor systems, monorails, clean room equipment, tray/pallet handler machines, vision software, lasers, assembly line equipment, and solar power equipment. The goal of their production is to increase efficiency, profitability, and energy conservation for those who use their products. Facilities are located in Canada, the United States, Europe, Southeast Asia, and China.

Challenge

Alliance was asked to design and manufacture a cleaning machine system for Hi-Pot testing on laminated solar panels. The solar panels are to be placed on racks measuring approximately 26” long x 17” wide x 12” tall but needed to accommodate racks and panels up to 36” long. The racks are then moved between testing tanks by employees with a production rate of one (1) rack every 150 seconds.

Solution

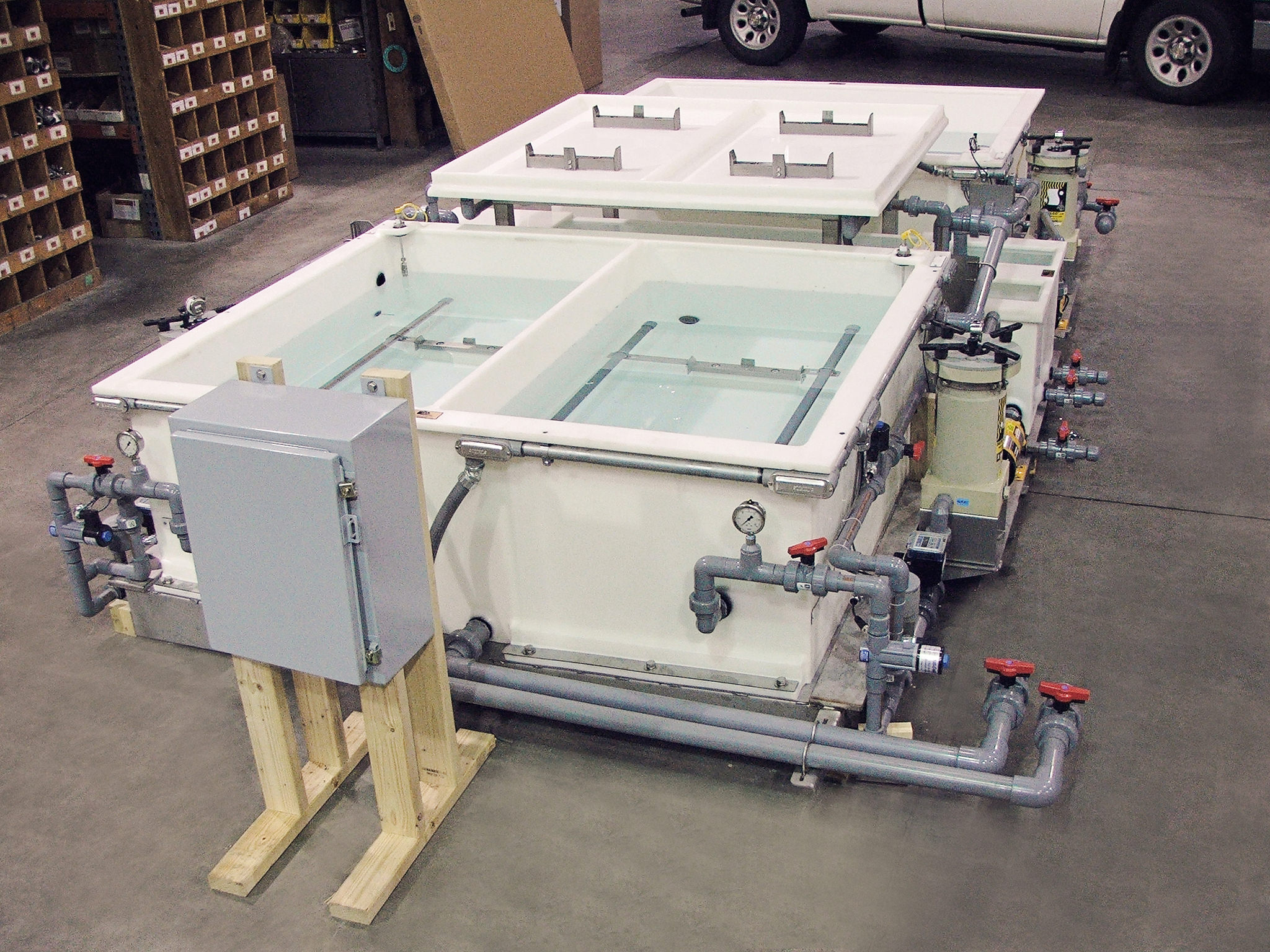

The Aquamate 6042 solar panel cleaning machine system was designed as a three (3) stage laminated solar panel cleaning system. The first stage consists of a dielectric, de-ionized water and detergent additive bath with agitating discharge holes. Tank capacity (make-up) is 40 gallons. The second stage is a drip recovery and drain board which allows the de-ionized water to flow back into the dielectric tank conserving as much de-ionized water as possible. The third and final stage consists of a 60 gal. de-ionized water rinse tank. Stage one (1) and three (3) dip tanks are constructed of ¾” thick polypropylene with sloped tank bottoms for ease of draining. The Aquamate 4836 pre-soak tank accompanies the wash system. The solar panels will exit the cleaning machine with moisture and move to a blowoff area that is done separately. Conductivity monitoring, temperature monitoring, tank agitating (sparging) system, flow indication sensors, micro filtration and solution low level sensors are all designed into the solar panel cleaning system. A custom color was selected by the customer. Overall dimensions are approximately 14’0” long x 7’6” wide x 2’6” high (top of dip tanks), 3’0” (high side of drain board).