One of the aspects that sets Alliance Manufacturing apart in the parts cleaning industry is that our machines are designed around the concept of ease of maintenance.

Time-consuming maintenance of cleaning machinery can equate to downtime and loss of production. Difficult, dangerous access can be a risk to employees and staff. Certain maintenance procedures can even put a strain on resources and money.

Full-Access Canopy:

The patented Full Access canopy, exclusive to Alliance Manufacturing, isn’t just for good looks. This innovative design allows safe and easy access to the interior of the machine, eliminating confined-space issues and allowing access to more of the machine than traditional door-style interior access. It’s quick and easy to remove the canopy segments by unlatching and removing. Interior components can be cleaned and adjusted from all areas of the machine interior.

Hinged Cleanout Doors

Hinged tank cleanout doors allow quick access to the solution tanks without the need for tools. These cleanout doors now come standard on all Alliance parts washers. Not only are the doors easy to open, but they are fabricated so that the opening is flush to the tank bottom for easy debris removal. Debris can then be removed from the tank by the use of a squeegee.

Quick-Release Spray Nozzles

Quick-release spray nozzles also come standard on all Alliance machines, though multiple nozzle styles are offered. The quick-release nozzles can be removed from the interior spray piping simply by unhooking them, without the need for tools. When cleaning extra dirty parts, nozzles can become covered in dirt, grime, and grease. To keep them spraying effectively and to avoid machine downtime, it is imperative to be able to remove, clean, and replace the nozzles quickly.

Slide-Out Spray Manifolds

Another innovative Alliance exclusive, the slide-out upper and lower spray manifolds provide safe cleaning and maintenance options for the interior spray piping. Not only can the nozzles themselves be removed easily, but now access to all the nozzles is easier and requires less maneuvering inside of the machine. The machine frame is designed so that both upper and lower spray manifolds can be easily removed. Typically, removing lower spray nozzles is problematic due to limited access, but not with an Alliance machine.

Drop-In Heating Elements (XE Series only)

When heating elements go down, they need to be replaced quickly in order to keep the machine operating optimally. In the past, the entire tank would need to be drained in order to remove the immersed heating elements. This can be a time-consuming job, as well as a strain on resources like water and cleaning solution. Alliance has developed a drop-in style heating element for our XE Series washers, which can be removed and replaced without the need to drain the tank.

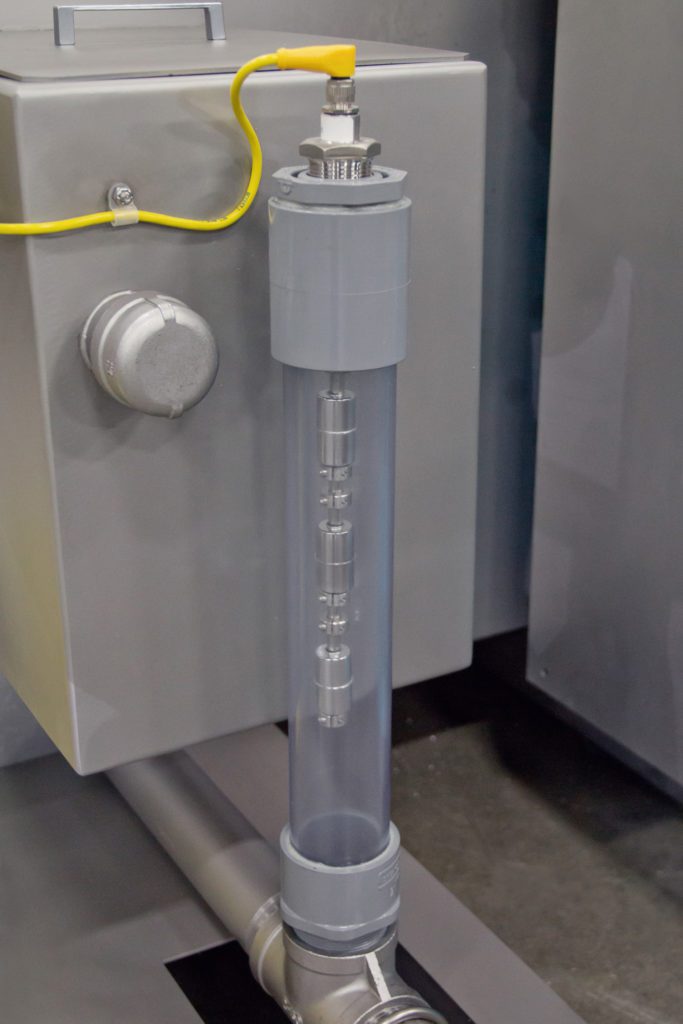

High Water Level Safety Shutoff

The new solution level control design includes three ball floats to keep the optimum water level for machine function. The top float acts as a safety shutoff in the event that the water fills beyond the full-level float, to prevent the tank from overflowing. An overflow would not only waste water and cleaning chemical, but would cost time for cleanup.

Shed Sheet Spray-Down

Additional nozzles can are added above the shed sheets to direct debris into the solution tank. This debris will then be caught in the filtration system so that it can be easily removed. This shed sheet spray system reduces maintenance labor by keeping the interior of the machine cleaner for longer periods of time.