Customer Background

Customer is a precision CNC machining company serving automotive, heavy equipment, and off-highway industries, specializing in complex, high-volume components. For transmission manufacturers, it delivers parts with tight tolerances and cleanliness standards where even small residue can impact performance.

Challenge

Transmission components have complex geometries and tight tolerances, making thorough cleaning of oils, chips, and contaminants challenging. The customer needed a conveyorized index cleaning system that ensured consistent cleanliness while meeting production and automotive standards.

Solution

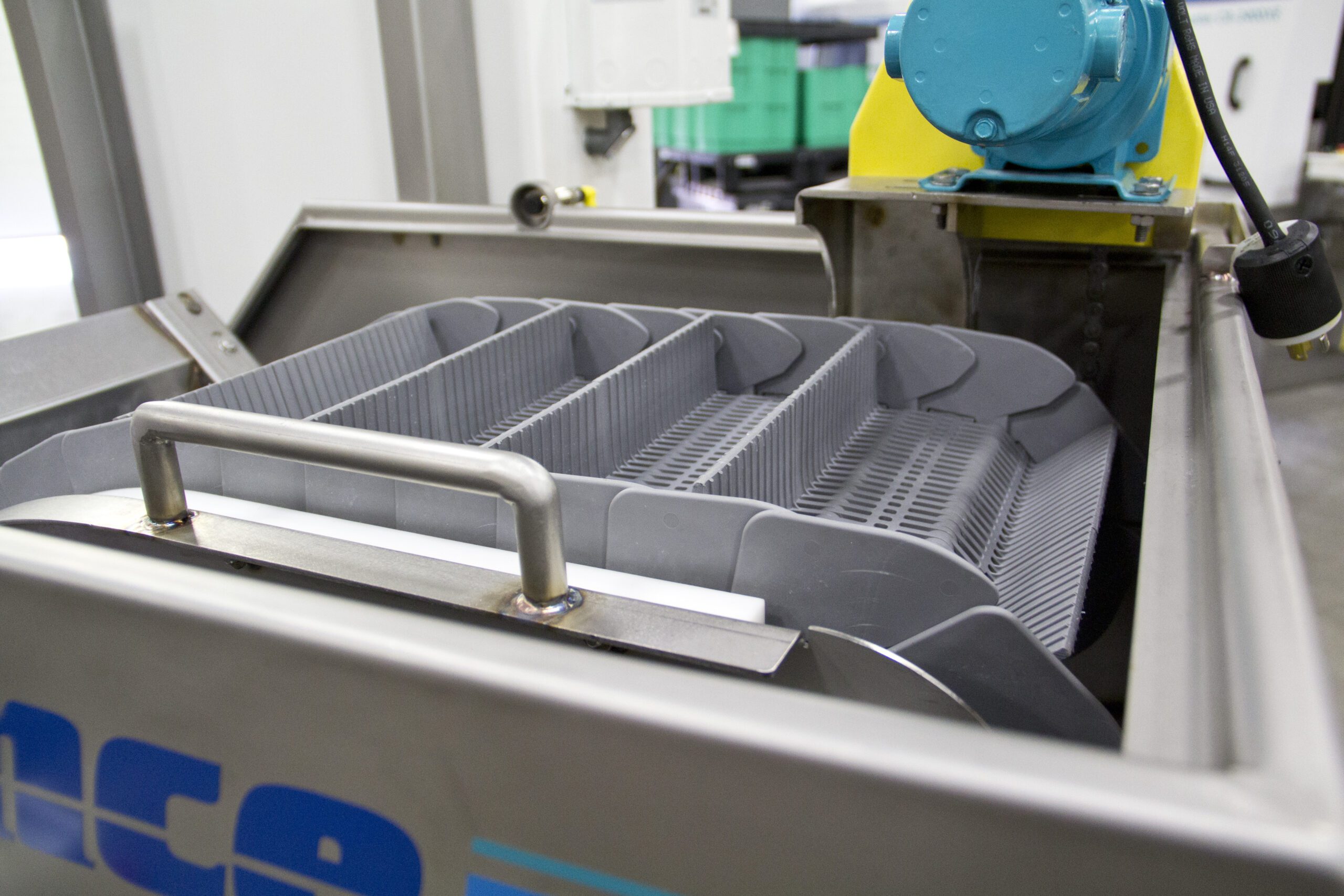

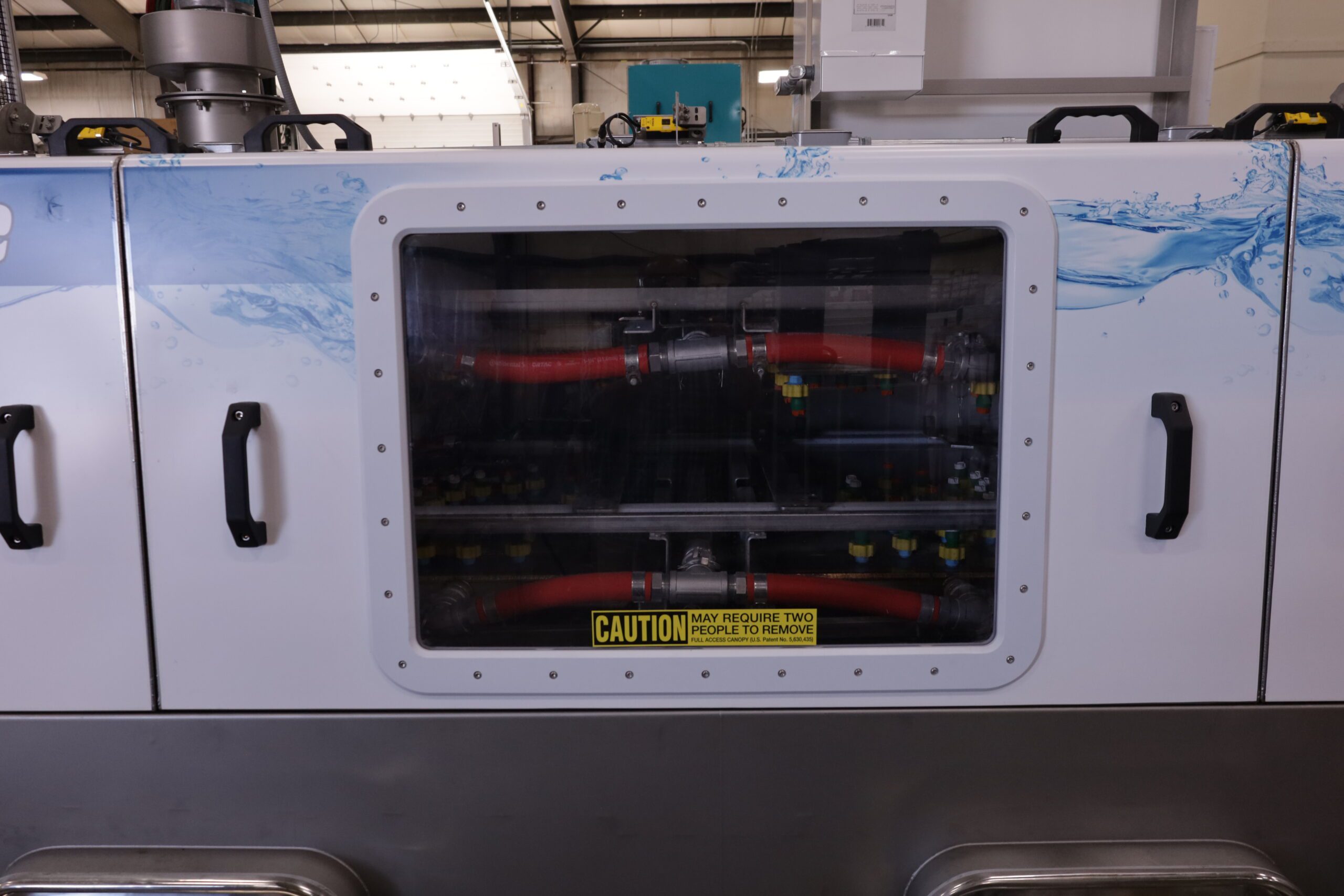

A conveyorized indexing cleaning system was built to deliver precise, repeatable cleaning to all surfaces, including internal passages, while maintaining production throughput and strict cleanliness standards.

Cleaning Method

High-pressure aqueous sprays with targeted agitation were ideal for this application because they clean all external and internal surfaces, followed by a heated blowoff to ensure thorough, residue-free drying.