Customer Background

A leading global manufacturer and integrator of precision rotary transfer style machining centers for automated production of automotive, medical, defense, aerospace and other components.

Challenge

Customer required a conveyorized cleaning system for integration into an automated manufacturing cell for processing machined aluminum fuel system components supplied a major North American small engine manufacturer. Requirements included cleaning multiple holes and internal passages present on the part, while allowing no residual contaminants larger than 175 microns. In addition, the machine needed to fit within a specified manufacturing cell and accommodate automated loading and manual unloading of 4 part groupings every 26 seconds.

Solution

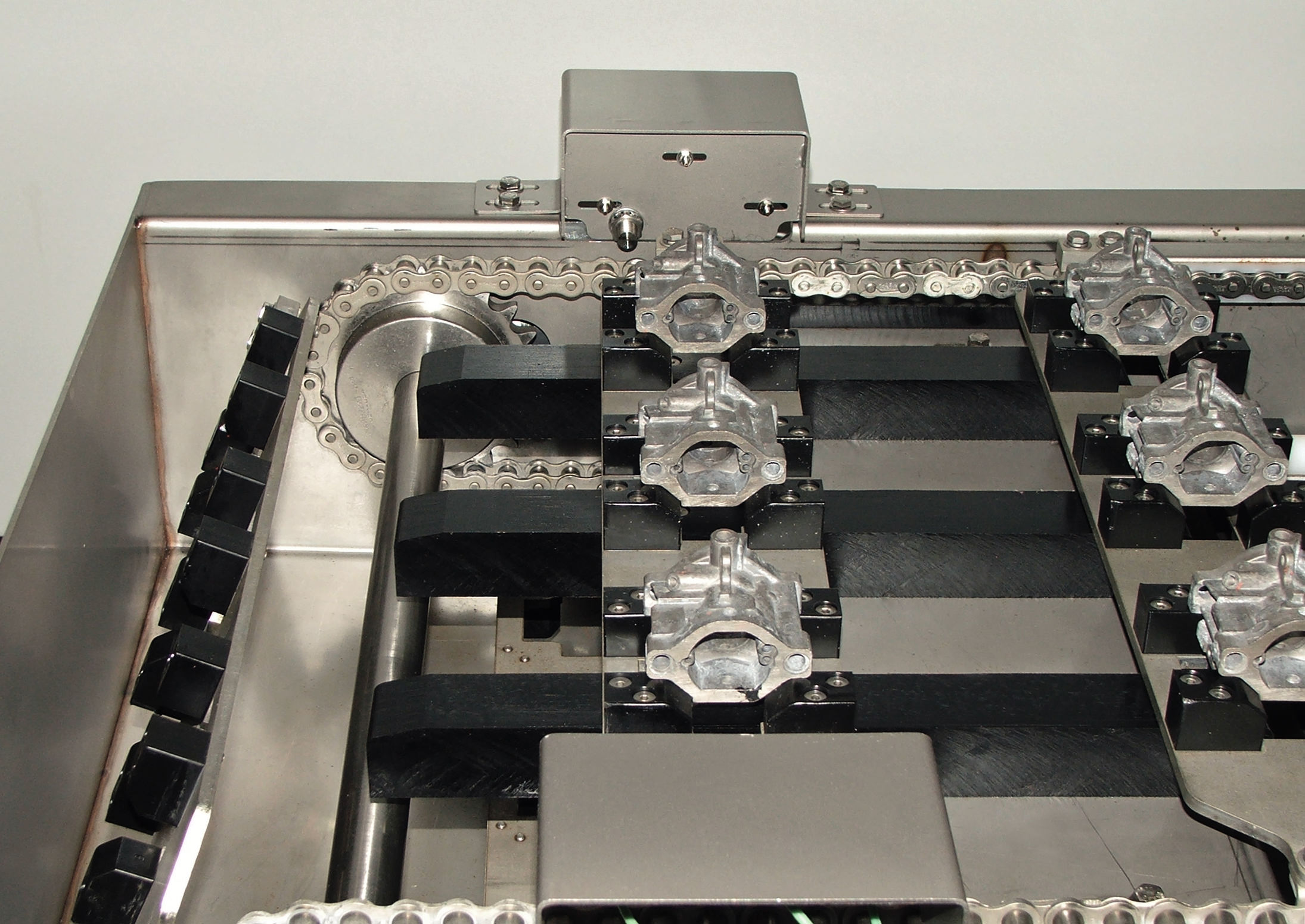

Alliance provided an Aquamaster CI-2400E indexing conveyorized parts cleaning system with wash, rinse and heated blowoff modules. Custom fixtures engineered to hold 4 parts for optimal cleaning, rinsing and drying were utilized in conjunction with pneumatic positioning devices and fiber optic sensors to insure precise transfer of parts from the automated loading equipment to the cleaning system. The unload conveyor was equipped with product sensors and a push button for activation by the operator to advance the conveyor after the unloading of parts.