Customer Background

Customer is a global technology leader in powertrain solutions. Their focus is on developing leading powertrain technologies that improve fuel economy, emissions, and performance.

Challenge

The customer required an inline cleaning system for removing deburring residue from a omation devices. Part orientation on the conveyor was critical for cleaning specific surfaces and passageways. The machine needed to be designed to handle one part every 14 seconds.

Solution

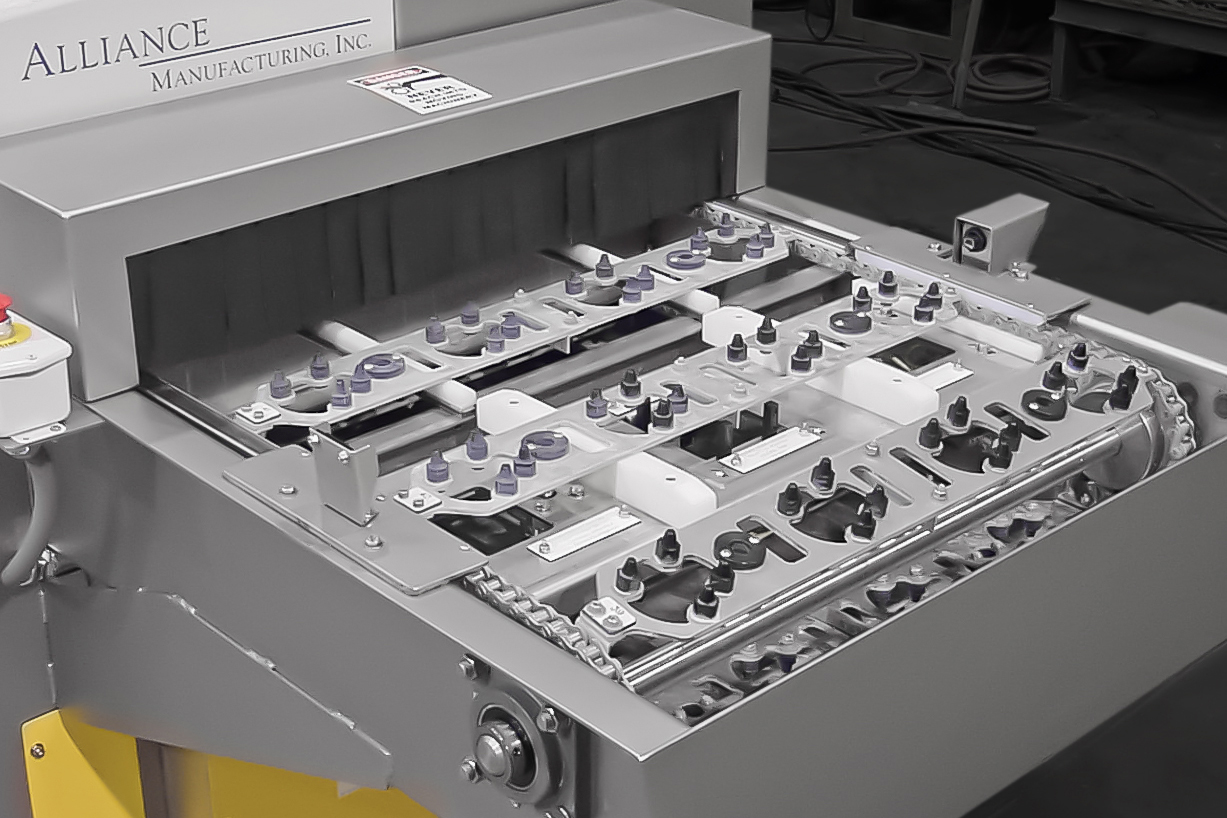

Given the critical nature of the tight passageways on the rotor, Alliance suggested an Aquamaster CC-3000E parts cleaning system with servo-driven indexing conveyor. The machine is designed to handle multiple parts on a custom-designed part fixture. The conveyor was designed to accommodate automatic loading and unloading of four parts per fixture. The conveyor was designed to stop in index positions in the wash, rinse, and blowoff stages. Pneumatically actuated spray manifolds descend onto the part at designated index positions for strategic cleaning and drying of horizontal holes and other part features.