Customer Background

The customer is a leading supplier of robots, CNC systems, and factory automation. They also produce industrial IoT products. It is one of the largest and most familiar automation companies.

Challenge

The customer needed to clean various electronic parts for a refurbishing operation. Parts included printed circuit boards, servo components, spindles, and power supply units. The parts were contaminated with cutting oils, soluble coolant, chips, and various soils.

Solution

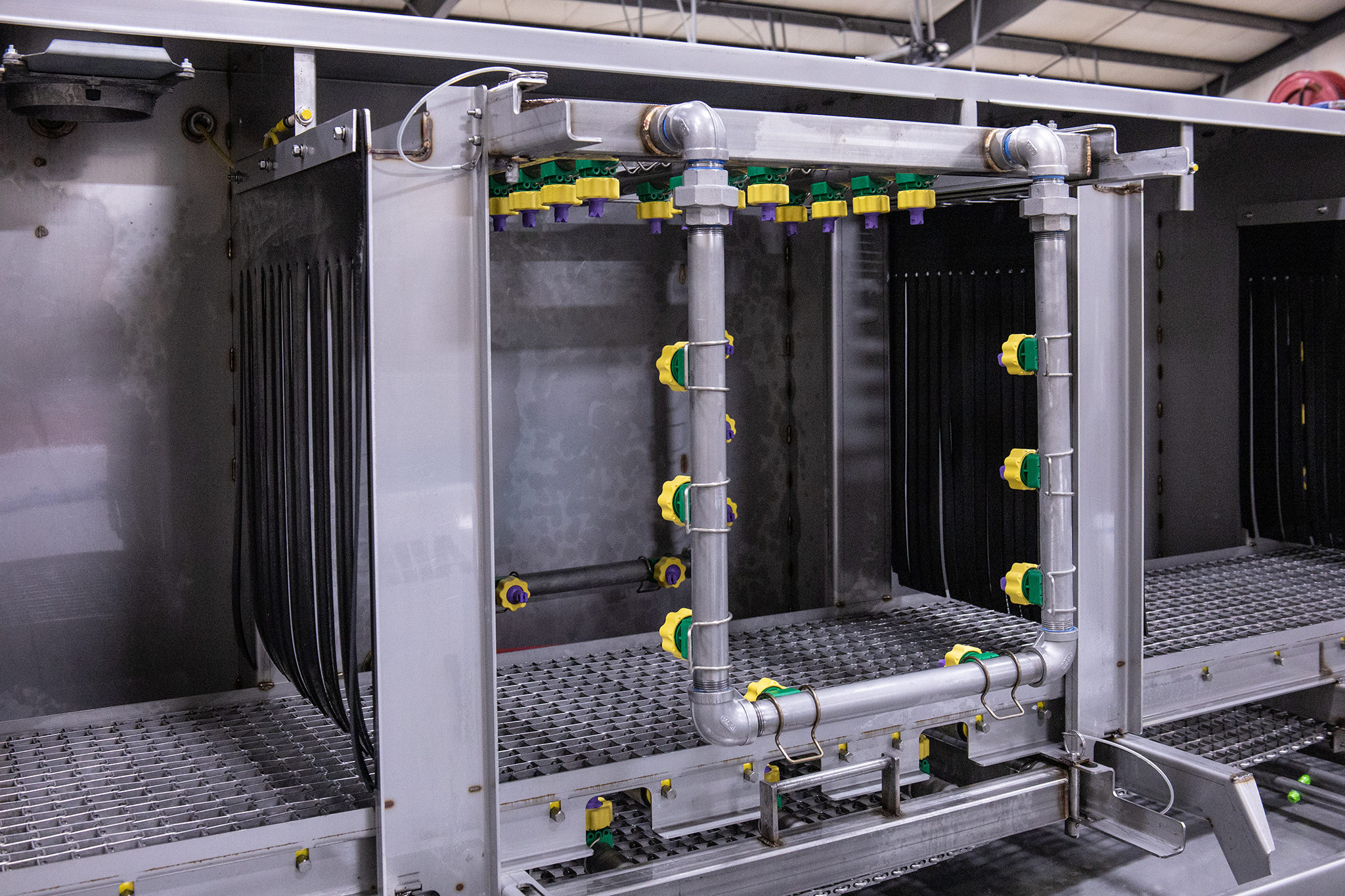

Alliance provided the Aquamaster CB-1800E belt washer. This style of washer allows for a variety of parts to be run simultaneously. The belt is 18″ wide and clearance is 18″ high which can accommodate large parts. This machine includes multiple zones, including a wash, rinse, fresh water de-ionized rinse, and heated blow-off to remove as much moisture as possible. Alliance’s exclusive pull-out spray headers allow for quick and easy nozzle maintenance. Also included are dual exhaust fans, a solution heat auto-timer, micro-filtration with a contamination sensor, chemical injection system, and an oil coalescer. A 10 foot long gravity roller conveyor is added to the unload end for part management.

Cleaning Method

Aqueous cleaning was chosen due to the variety and large size of parts needing to be cleaned. The customer needed to have a machine available to continually feed parts for cleaning as needed.