Customer Background

The customer is a U.S.-based manufacturer of professional-grade hand tools, used primarily for electrical and utility applications.

Challenge

The customer needed a machine that could remove machine oils from various sizes of pliers. The pliers needed to exit visually clean and as dry as possible without the use of a heat blower.

Solution

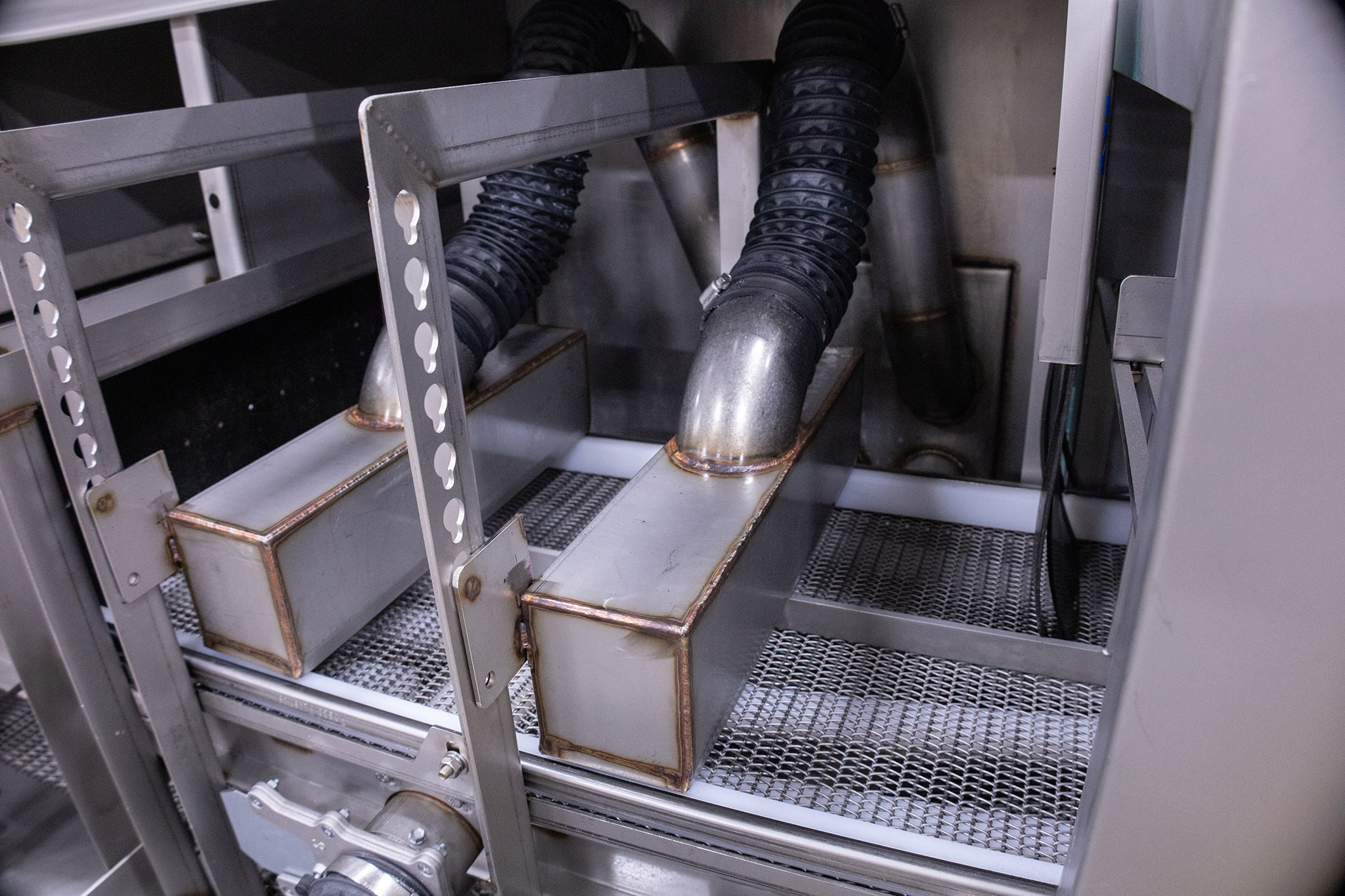

Alliance provided an Aquamaster CB-1600E conveyorized belt aqueous parts washer with a woven-wire conveyor belt. The conveyor includes a center lane divider and side guards to reduce the gaps on the sides of the belt. In the blowoff zone, air knives are adjustable for height. Other features include a mist collector, oil coalescer, chemical injection, and a micro-filtration chamber.

Cleaning Method

Aqueous cleaning was chosen because a simple inline process was ideal for cleaning hand tools.