Customer Background

Customer is a provider of automation systems for a variety of industries. They offer solutions for manufacturing, assembly, and testing operations.

Challenge

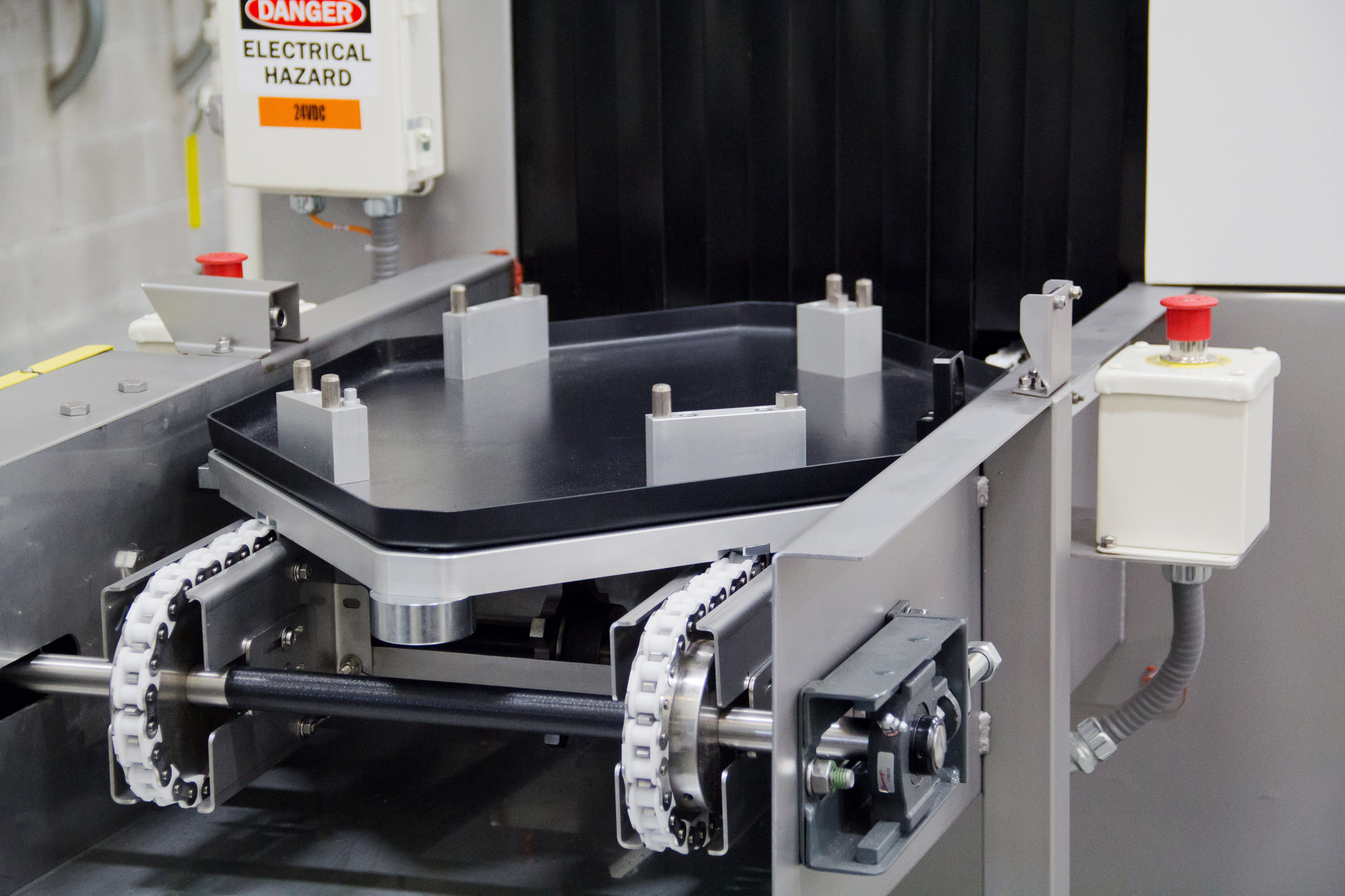

The customer needed a conveyorized washing system for aluminum/plastic part pallets used in automotive component production. Typically the pallets would be empty, but the machine needed to have enough clearance for times when parts would be placed on the pallets. The pallets were contaminated with machine coolant and chips and needed to exit the industrial automotive pallet washer visually clean and with gross amounts of moisture removed. The cycle time is one pallet every 20-25 seconds.

Solution

Alliance provided an Aquamaster CC-2000E conveyorized chain parts washing system with wash and ambient blowoff zones. Alliance’s dual chain conveyor is designed for handshake interface with the customer-supplied flex chain conveyor. Flex chain conveyors are not suitable for traveling through a wash system, and therefore pallets need to be transferred to a conveyor designed for wash applications. The machine process zones included a heated wash, heated rinse, and ambient blowoff modules. The high-velocity ambient blowoff was designed to strip gross amounts of moisture from pallets prior to exiting the wash system. Optional accessories used in the design included dual mist collectors for exhausting steam from the machine, eliminating the need for external ducting. Dual micro-filtration chambers for wash and rinse zones were included for filtering fine particulate. A belt-type oil skimmer removes floating oils and contaminants. The pallet washer machine was designed to meet exacting automotive electrical and mechanical specifications. An HMI control was incorporated for easy operator interface. Electrical panel and machine components were painted in a customer-specified paint color.