Customer Background

A global leader in consulting, design, build, operations and program management with more than 23,000 employees in regional offices worldwide serving the chemical, nuclear and defense industries, and governmental agencies.

Challenge

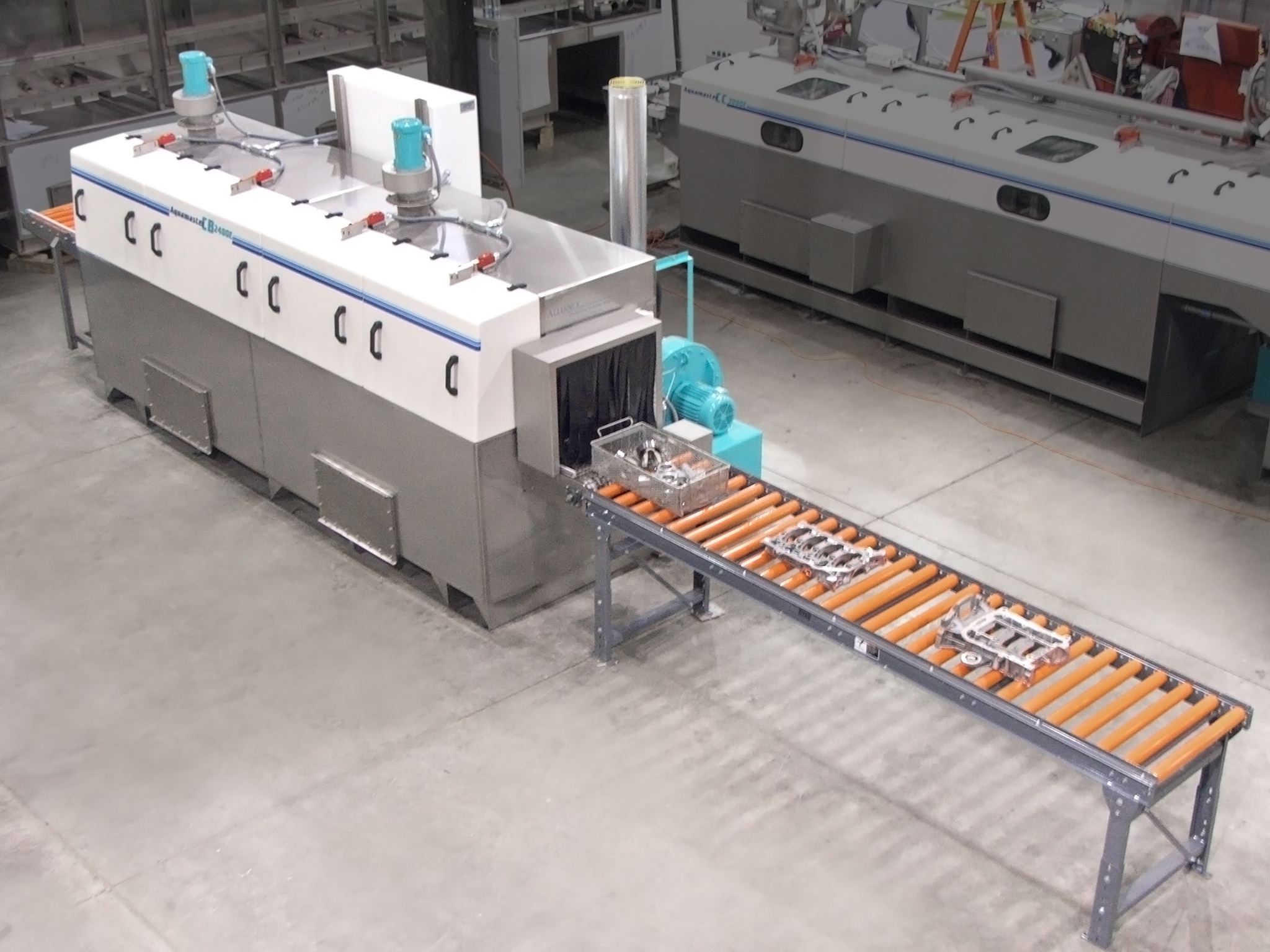

Customer required a conveyorized system to clean a wide variety of aircraft landing gear components processed in baskets. Additionally, the machine needed to include a special entrance conveyor for ease of loading baskets up to 31” long, and must allow parts to accumulate on the exit conveyor in the event that unloading does not occur within a given timeframe.

Solution

Alliance provided an Aquamaster CB-2400E conveyorized parts cleaning system with wash and ambient blowoff modules, and a 24” wide x 18” high product opening. A high-volume pump and additional solution heating elements were employed to remove the very heavy soils present on the parts. Extended load and unload conveyors were equipped with gravity-roller sections to accommodate handling of the baskets. The unload conveyor allowed for an accumulation of multiple baskets to prior to removal. A sensor was utilized to automatically disengage the conveyor drive motor in the event that baskets of clean parts fill the exit conveyor.