Customer Background

An advanced manufacturing engineering firm specializing in the integration of automated manufacturing equipment for automotive, small engine, and a variety of other industries.

Challenge

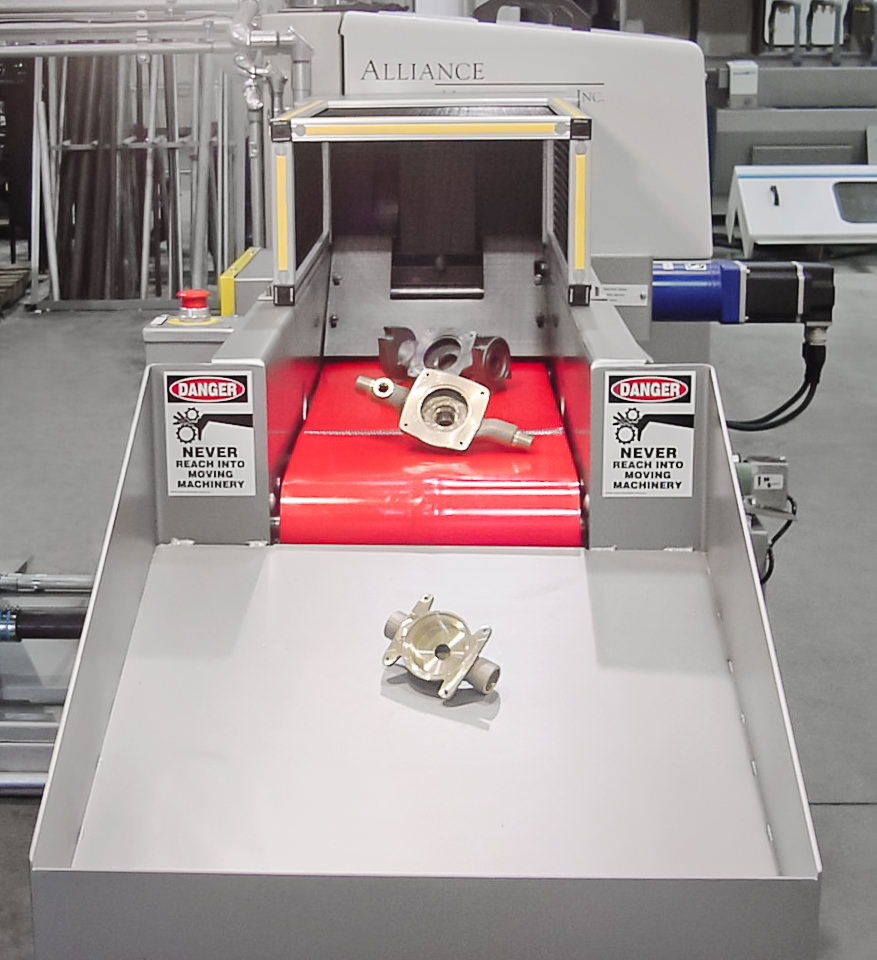

Customer required an indexing conveyorized cleaning system to process machined components at 30-second intervals. The machine needed to be integrated into a manufacturing cell and interface with automated loading equipment and allow for manual unloading with part accumulation on the exit conveyor.

Solution

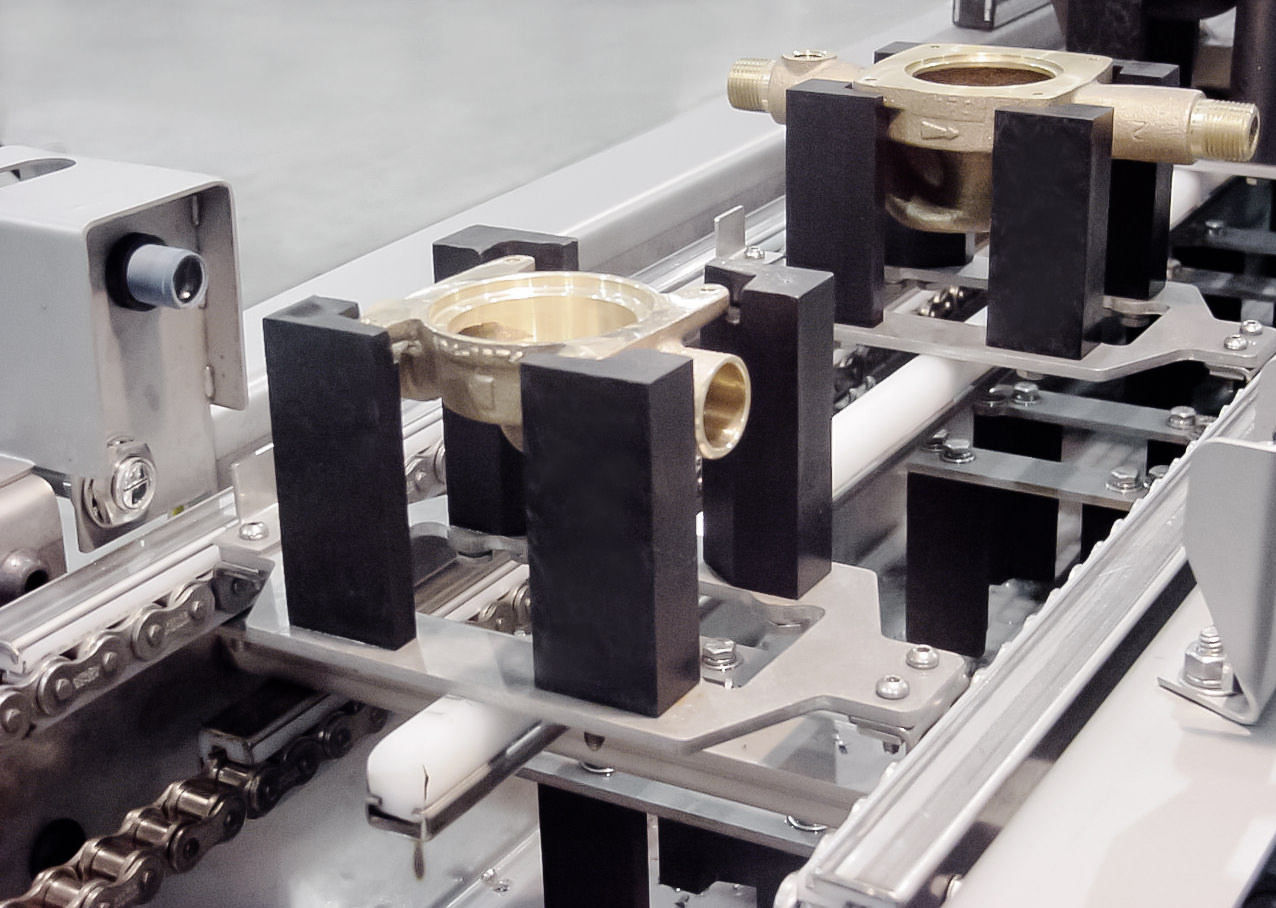

Alliance provided an Aquamaster CI-1200E indexing conveyorized parts cleaning system with wash and ambient blowoff modules. Custom part fixtures and a servo-drive conveyor drive system were utilized to insure precise loading, optimal cleaning, and efficient transfer of parts through the process. The load and unload conveyors were equipped with 80/20 mesh guarding for operator safety, and the unload conveyor was equipped with a gravity-roller section for part accumulation.