Customer Background

Manufacturer of steel forged components in small to medium quantities. The company is based in the midwest. They manufacture steel forged dies and other components to be used in a variety of industries including construction, agriculture, transportation, petro chemical, industrial power, defense to name a few. The company handles all steps of the manufacturing process from engineering to producing the die, machining, heat-treating, and ordering.

Challenge

The customer was seeking a steel washer and cleaning machine to remove oil, grease, and manufacturing soils from their forged dies and fixtures. The washer was to accommodate products of varying sizes and weighing up to 2,000 lbs.

Solution

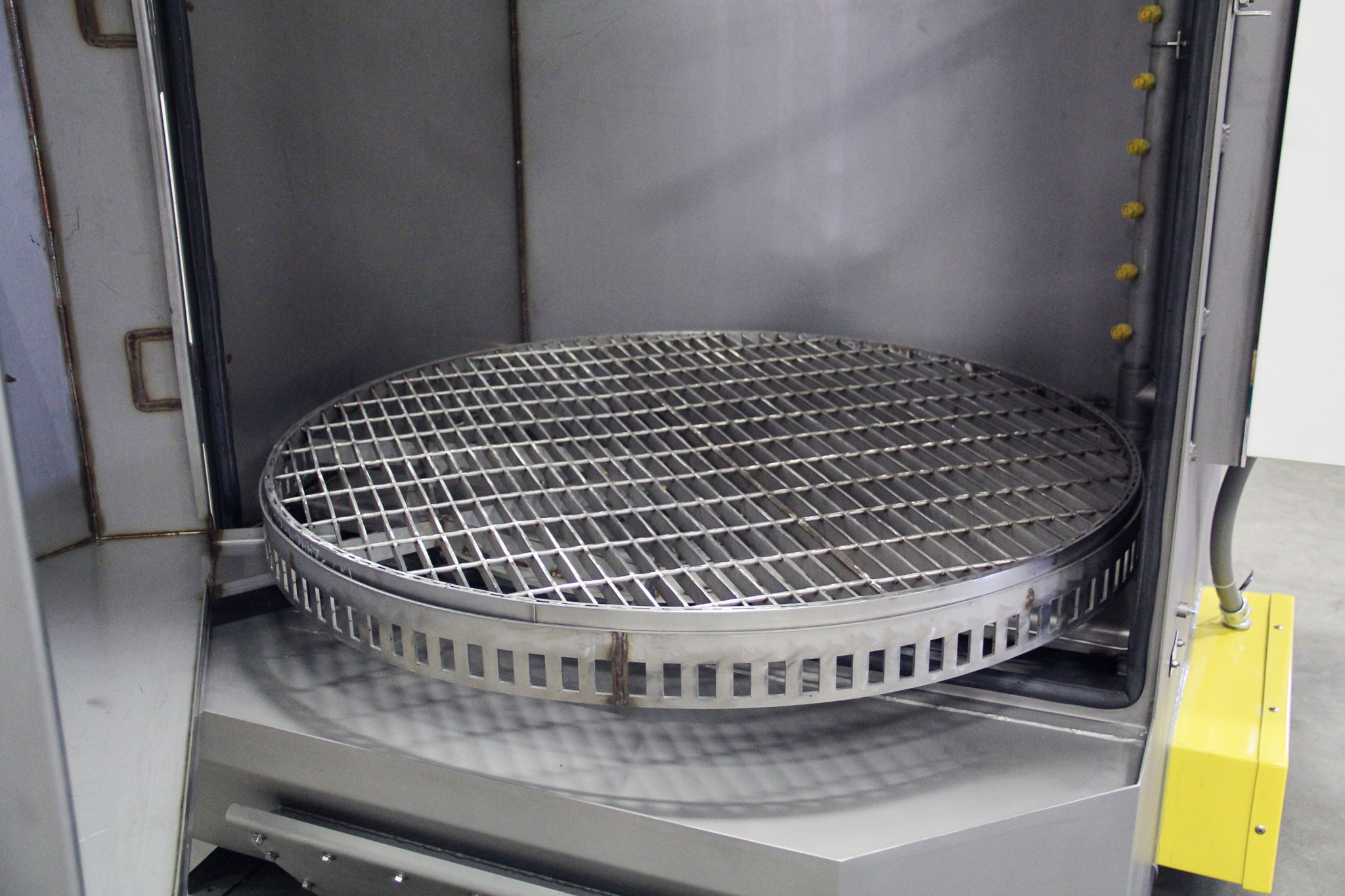

Alliance provided an Aquamate RF-4860 rotary table, front load parts washer. The cleaning machine product table is 48” in diameter and constructed with heavy-duty stainless steel grating. Maximum product clearance is 60” tall. Table-stabilizing casters included with the machine are designed to support loads up to 3,000 lbs and keep it evenly distributed. The tank is also constructed of stainless steel. A belt-type oil skimmer, exhaust fan, chemical injection system, dual micro-filtration, solution heat auto-timer, and an additional intermediate spray bar for low-profile parts are all included in the design.