Customer Background

Customer is a leading global supplier of technology and services in the areas of automotive and industrial technology. As one of the largest North American automotive suppliers, they develop, manufacture, and supply precision components and systems (including body electronics, chassis, and powertrain products) for vehicle manufacturers worldwide. The company has multiple locations throughout the world.

Challenge

The customer needed an inline cleaning system for removing machine coolant, chips and E-coat chips/flakes from ductile cast iron disc brake calipers. Given the critical nature of the component, the machine needed to be able to meet a stringent part cleanliness specification. The system needed to be capable of cleaning and drying 600 parts/hour.

Solution

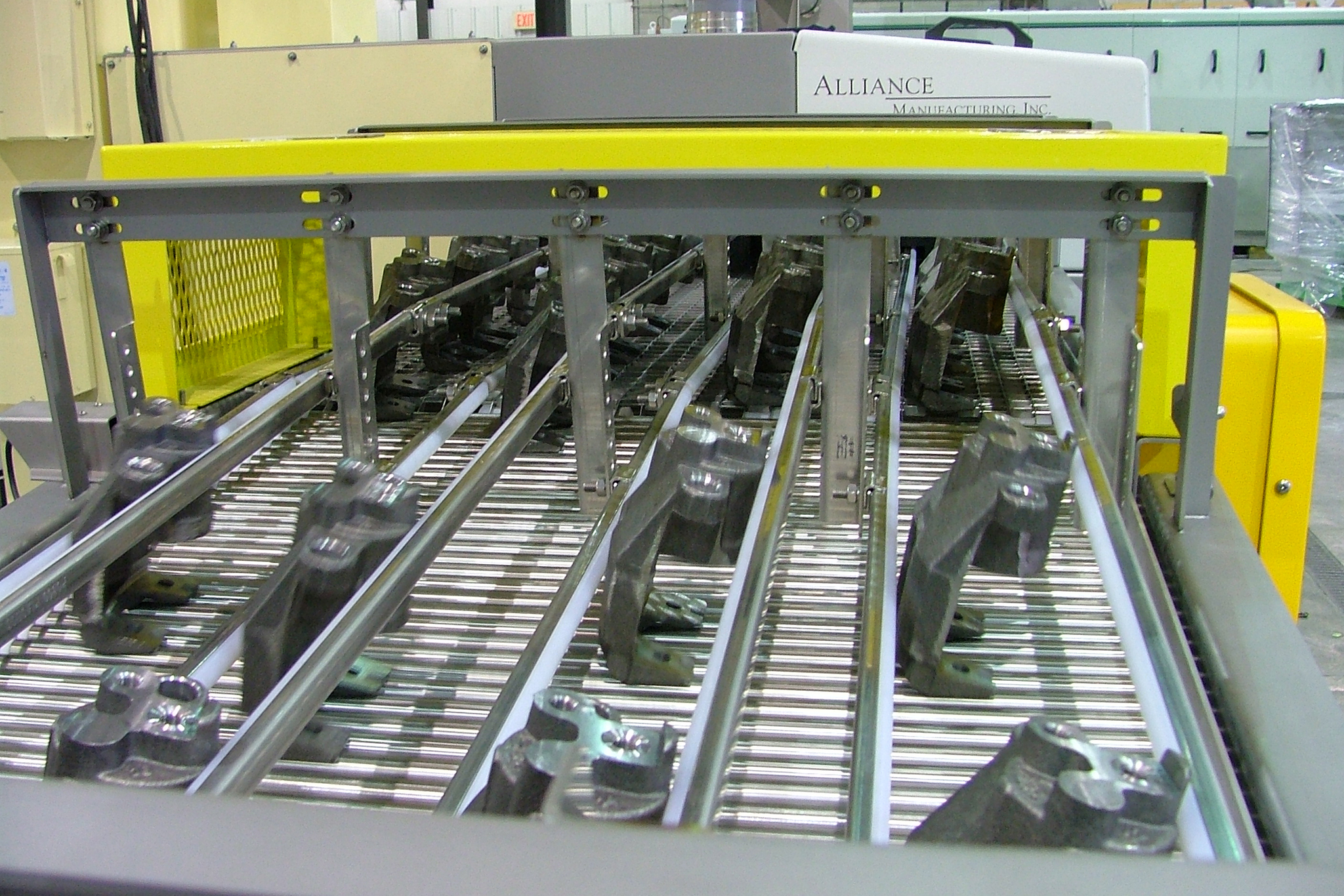

An Aquamaster CB-3000X conveyorized parts cleaning system with a wash, rinse (rust inhibit) and ambient blowoff modules was provided. The machine included a 30″ wide conveyor utilizing side guides and lane dividers to create four equally spaced product lanes. Particulate filters were provided on both the wash and rinse process zones for filtering the cleaning solution. The rinse filter system included a dual chamber for step down filtration to an absolute rated 20 micron cartridge. The brake caliper parts washer system provided satisfied the customer’s demanding cleanliness specifications.