Customer Background

Customer is a Tier 1 manufacturer of shock absorbers, steering systems, and differential gears to be used in the production of automobiles, motorcycles, and ATVs. Products are used by many major manufacturers. Plants and offices are located around the U.S., while its parent company is based in Japan. They specialize in using lightweight, high-tension materials. The company focuses on efficiency and energy conservation while maintaining performance, durability, and reliability.

Challenge

The customer was seeking a conveyorized parts washing system to remove manufacturing soils from 1” diameter x 20” long cylinders after production. They had to appear clean and be free of oil. Almost complete dryness was desired after a heated wash.

Solution

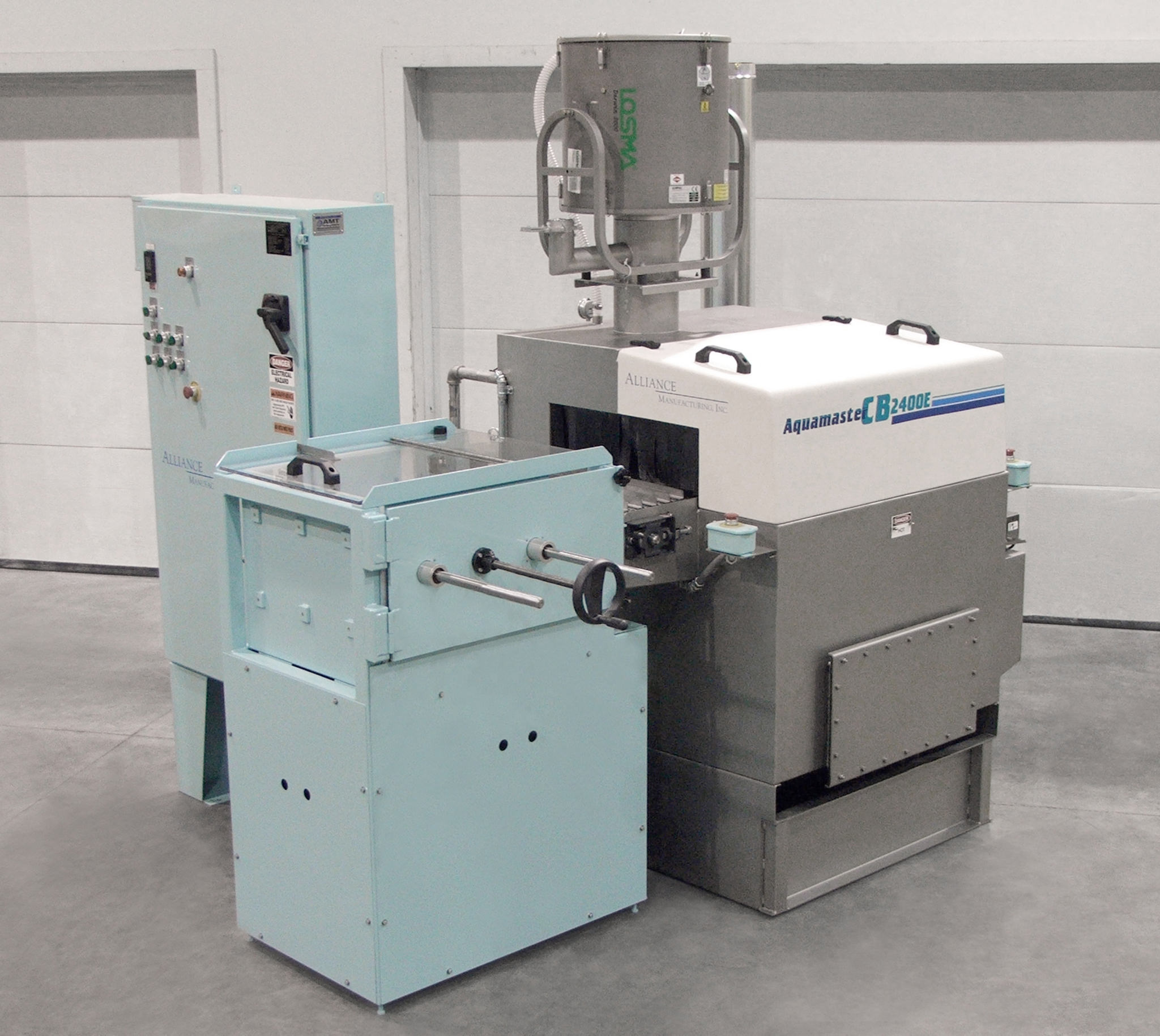

Alliance provided an Aquamaster CB-2400E compact conveyorized belt washer with a heated wash and ambient blowoff. The conveyor speed is adjustable for varying production rates. The mesh-style conveyor is angled at a slight 3% grade through the wash and blowoff zones to aid in the drying process. A sound-dampening package was included in the ambient blowoff zone to lower noise levels to around 85 dBa or lower. Light curtains were added for operator safety. The customer opted to include a mist collection exhaust system, solution heat auto-timer, micro filtration, oil skimmer, and a custom designed adjustable (for shorter cylinders) loader for automatic positioning of cylinders onto the conveyor.