Customer Background

Customer designs and manufactures automated parts handling systems, parts washers, assembly machines, and other specialized machines for a wide range of industries globally.

Challenge

A parts washer was needed for cleaning V8 and V6 camshafts, at a rate of one camshaft every 35 seconds or less. These camshafts were contaminated with water-soluble coolants and chips from the manufacturing process. Cleanliness requirements were to have under 10 mg total mass, and the camshafts had to be drip-free for one minute after exiting the washer.

Solution

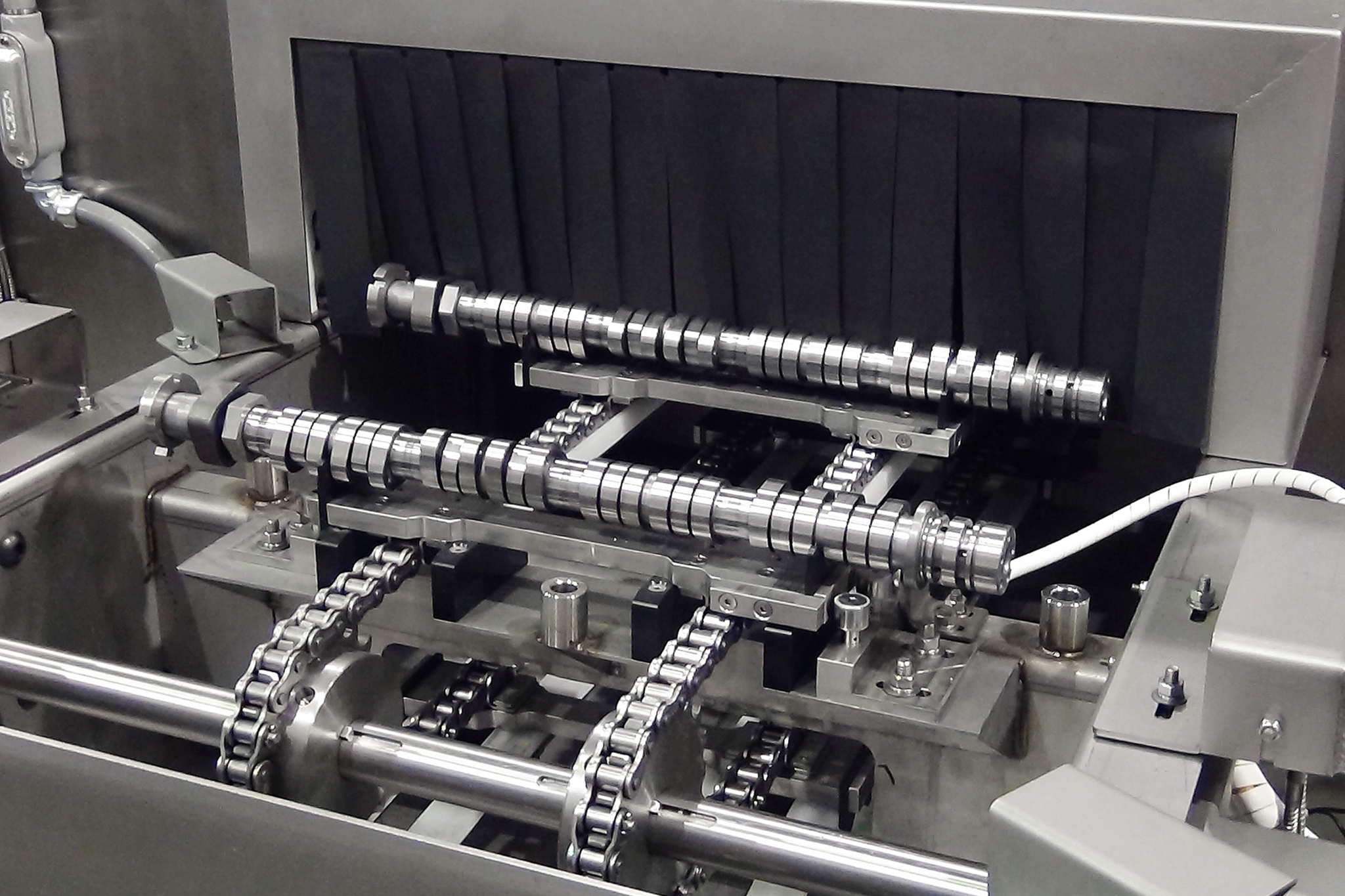

Alliance provided an Aquamaster CC-2400 indexing parts washer with wash and blowoff modules. The conveyor is an indexing system equipped for automated part loading and unloading. Dual stainless steel chains with part fixtures convey parts through the camshaft cleaning system. Conveyor speed is pre-set for maximum efficiency, but can be adjusted in the servo program inside the motor control cabinet. A part fixture holds one part on a chain conveyor with sensors located at the load and unload positions. Parts stop at index positions for precise cleaning operations. Light curtains were added for safe operator manual loading. A contamination sensor for the micro-filtration filter bag was added along with an indicator light. High-velocity air systems allow for a compressed air blowoff. A part cooling system was added to the end of the camshaft cleaning cycle and was engineered to lower the part temperature to within 5°F of room temperature. The cooling system is sized based on a cycle time of 25.7 seconds per camshaft with an estimated weight of 5 pounds. The camshaft temperature entering the cooling system is approximately 130°F, exiting to a room temperature of approximately 70°F. Safety glass windows suitable for water immersion and interior lighting are added to each door for process viewing.