Customer Background

Customer is a leading manufacturer and supplier of stamped mechanical and electronic vehicle locks and keys, ignition lock housings, and access control products.

Challenge

The customer needed a washing system to clean and dry various small steel stamped locking components for vehicle lock and security. Alliance needed to meet a production rate of 60 parts per minute. The customer specified cleaning requirements was that the components needed to be visually clean, oil-free and 100% dry upon exiting the washer.

Solution

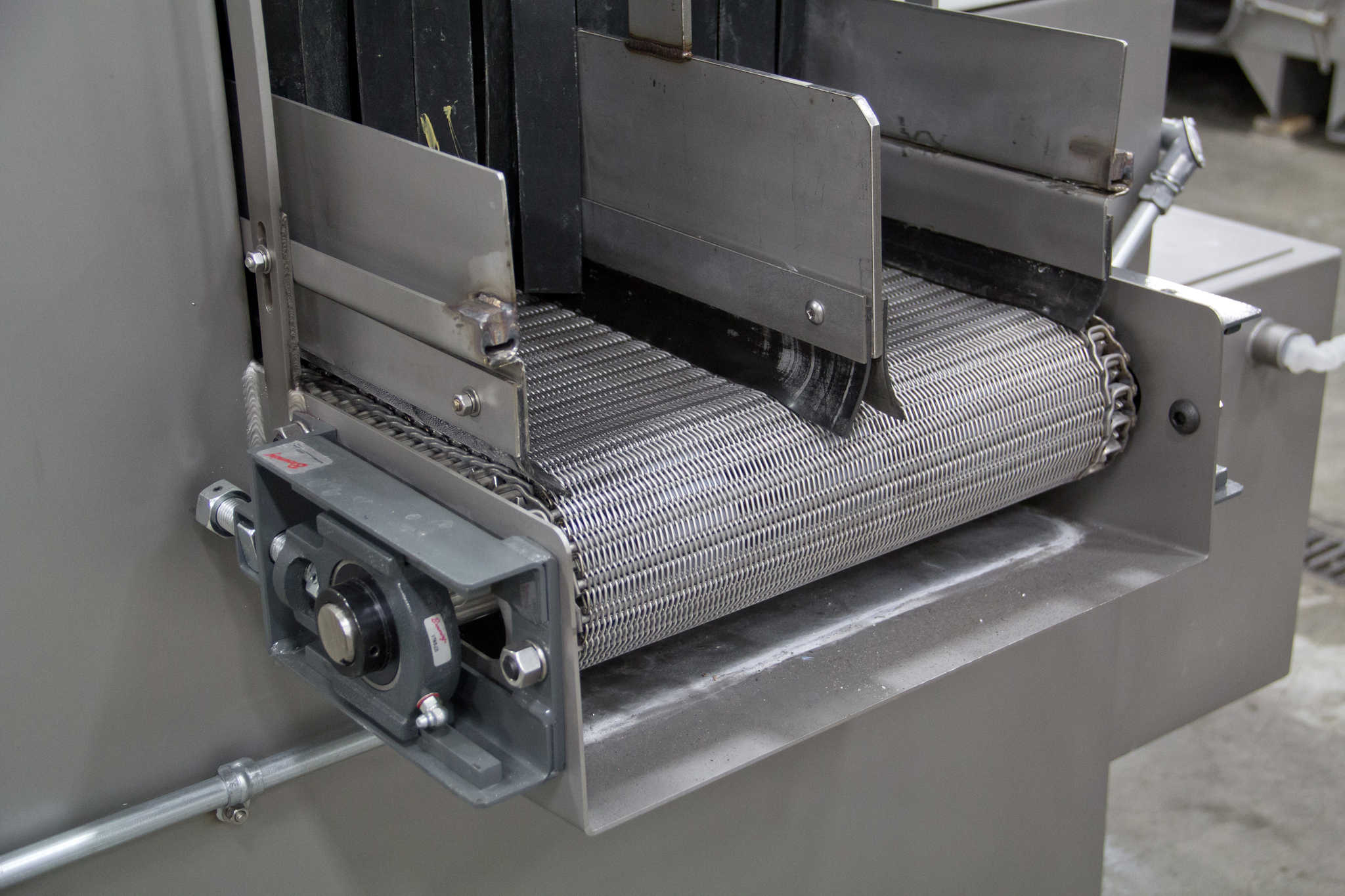

Alliance’s solution was an Aquamaster CB-1800E conveyorized belt cleaning system with wash, rinse, intermediate blowoff, and heated blowoff modules. This cleaning system utilizes an 18” wide stainless steel tight-mesh belt which is designed to accommodate small parts of varying sizes. A lane divider runs the center of the conveyor belt to keep parts separated for easier processing after cleaning. The heated wash and rinse helps to breakdown the oils and separate the oil from the part. The heated blowoff module ensures complete dryness on exit per customer specification. When removing oils from parts, it is important that oils are also removed from the tank water itself. An Aqualescer oil coalescing system is used to continually skim oil from the tank solution. To further enhance the cleaning process, optional accessories included with this machine are dual exhaust fans, micro-filtration on both the wash and rinse modules, and a solution heat auto-timer. Lift-off canopy segments allow for easy interior access to the machine for routine maintenance. Hinged cleanout doors provide maintenance personnel quick and easy access to fully clean and remove any debris or particles from the bottom of the tanks. This stamped locking component washer has overall dimensions of 20’8” long x 6’6” wide x 6’0” high.