Rotary Front Load Cabinet Washers

Aquamate RF

Call us: 1-800-969-7960

The Aquamate RF rotary front load cabinet industrial parts washers are designed for batch processing and low-volume parts cleaning. Parts are placed on a rotary table and cleaned for a set period of time. Cabinet parts washers offer a space-saving and cost-effective solution to parts cleaning needs.

Request a Quote

Let our team configure the right parts washer for your application.

Alliance’s front load cabinet washers utilize a direct drive rotating table. Standard rotary table sizes include 30,″ 36,″ and 48″ diameters, but can be fully customized to suit specific applications.

For easy part loading and unloading, a hinged stainless steel door is provided. The top edge of the door is beyond the center of the turntable, allowing parts to be loaded and unloaded by an overhead hoist.

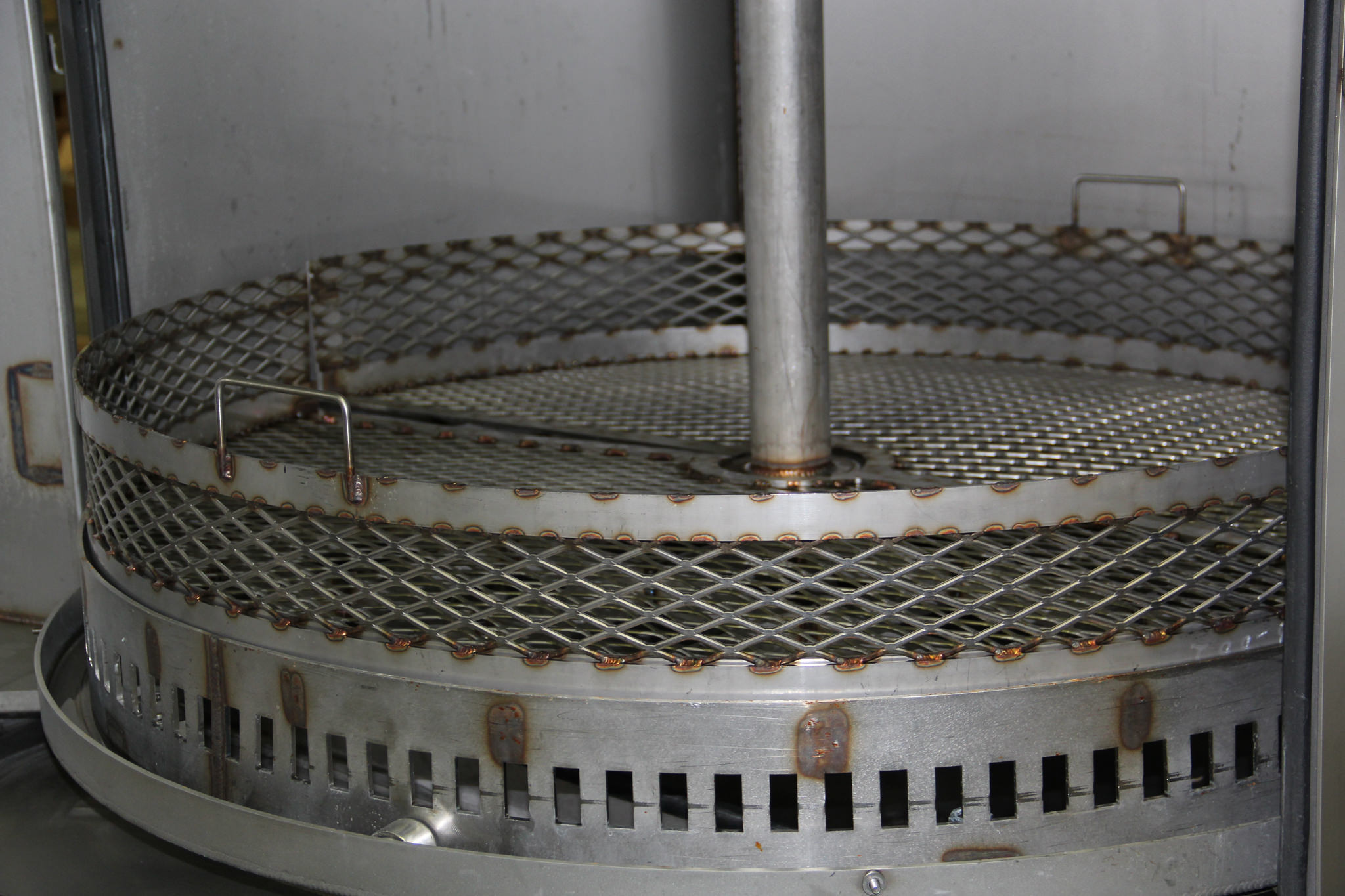

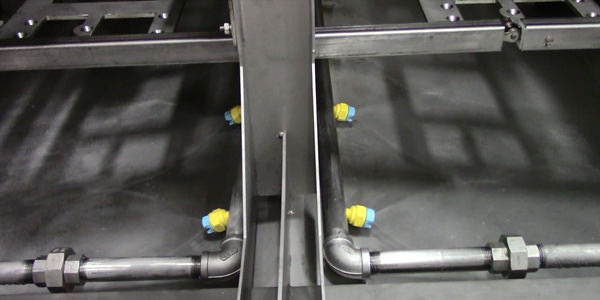

During the cleaning process, parts are rotated past multiple nozzles located above, below, and to the sides of the rotary table for fast and efficient cleaning. After cleaning, the spray system automatically shuts off and the table continues rotating to allow for drainage. The cycle stops and parts are manually unloaded. Timers are provided for controlling wash cycle and drain time durations. In addition, options such as exhaust fan systems, mist collection, oil coalescing, blowoff, etc. are also independently controlled by timers. Individual time control of cleaning functions provides flexibility for easy cleaning cycle customization.

Our rotary table cabinet washers include many standard features not found with competitors’ machines: Direct-drive turntables, tank clean-out doors, solution level control with low water safety shutoff, and internal debris rinsing. One unique feature of Alliance cabinet washers is a centerless bearing turntable. The turntable is supported at the circumference, eliminating the need for a center bearing. This prevents a cleaning blind spot and allows the operator to load parts anywhere on the turntable with uniform cleaning results.