Conveyorized Dip Parts Cleaning (913)

Customer: Precision metal stamping solutions for global industries Item to Clean: Stampings of various sizes Contamination: Light stamping oils and lubricants Process Parameters: Wash Cleanliness Required: Oil free

Cleaning Transmission Components (1099)

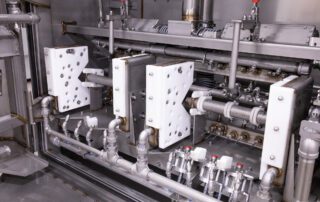

Customer: A leading transmission remanufacturer Item to Clean: Automatic transmission components for rear wheel drive transmissions. Contamination: Transmission fluid, oils, grease and road soils. Process Parameters: Dual Wash, rust inhibit

Building a High-Volume Parts Washer | Episode 1: Introduction

“Engineering, innovation, and craftsmanship — helping you clean better.” In this special video series, Ken from Alliance shares an inside look at the process of building these complex cleaning systems. Whether you’re looking for a

Cleaning High-Volume Beverage Components (800)

Customer: Food and beverage product manufacturer Item to Clean: Aluminum nitrous oxide charger bottles Contamination: Chips, tooling lubricants Process Parameters: Wash, rinse, heated blowoff Cleanliness Required: Visually clean, free

Ken’s SUITE Video | Aqueous Parts Washer (9-15-25)

Ken from Alliance here with a Suite message: Sustainable. Unique. Innovative. Timely. Economical. Ken’s SUITE Video | Aqueous Parts Washer System (9-15-25) Do you have parts that are tough to clean—such as castings, components

Aluminum Crankcase Parts Washer (#1076)

Customer: Leader in outdoor recreational vehicles Item to Clean: Aluminum crankcases, two halves Contamination: Machine coolant and chips Cleanliness Required: Cleanliness specification Dryness Required: Gross moisture removed Production

Welcome to the Alliance Manufacturing Blog — your destination for in-depth stories, product highlights, and expert insights from the world of aqueous parts washer innovation. Here, we share real customer case studies, engineering spotlights, and behind-the-scenes looks at how our team designs and builds everything from automated parts washer systems to specialized circuit board washer units for the electronics industry. You’ll also find coverage of new product developments, sustainability initiatives, and company milestones — all centered on advancing the science of clean parts.

Our blog also features Ken Manninen’s Suite video series, showcasing how each cabinet washer, industrial parts washer used in production, and even a used parts washer from our lineup reflects Alliance’s core principles: Sustainable, Unique, Innovative, Timely, and Economical. Whether it’s exploring the benefits of an aqueous parts washer versus a vacuum degreaser, or highlighting how automation is reshaping parts cleaning, our goal is to keep you informed and inspired by the technology, craftsmanship, and people behind every Alliance system — all proudly built in Wisconsin.