Customer Background

An innovative, leading manufacturer of components and controls for residential, commercial, industrial, and institutional HVAC systems, with manufacturing and distribution operations in North America and a sales network in South and Central America, the Middle East, and Asia.

Challenge

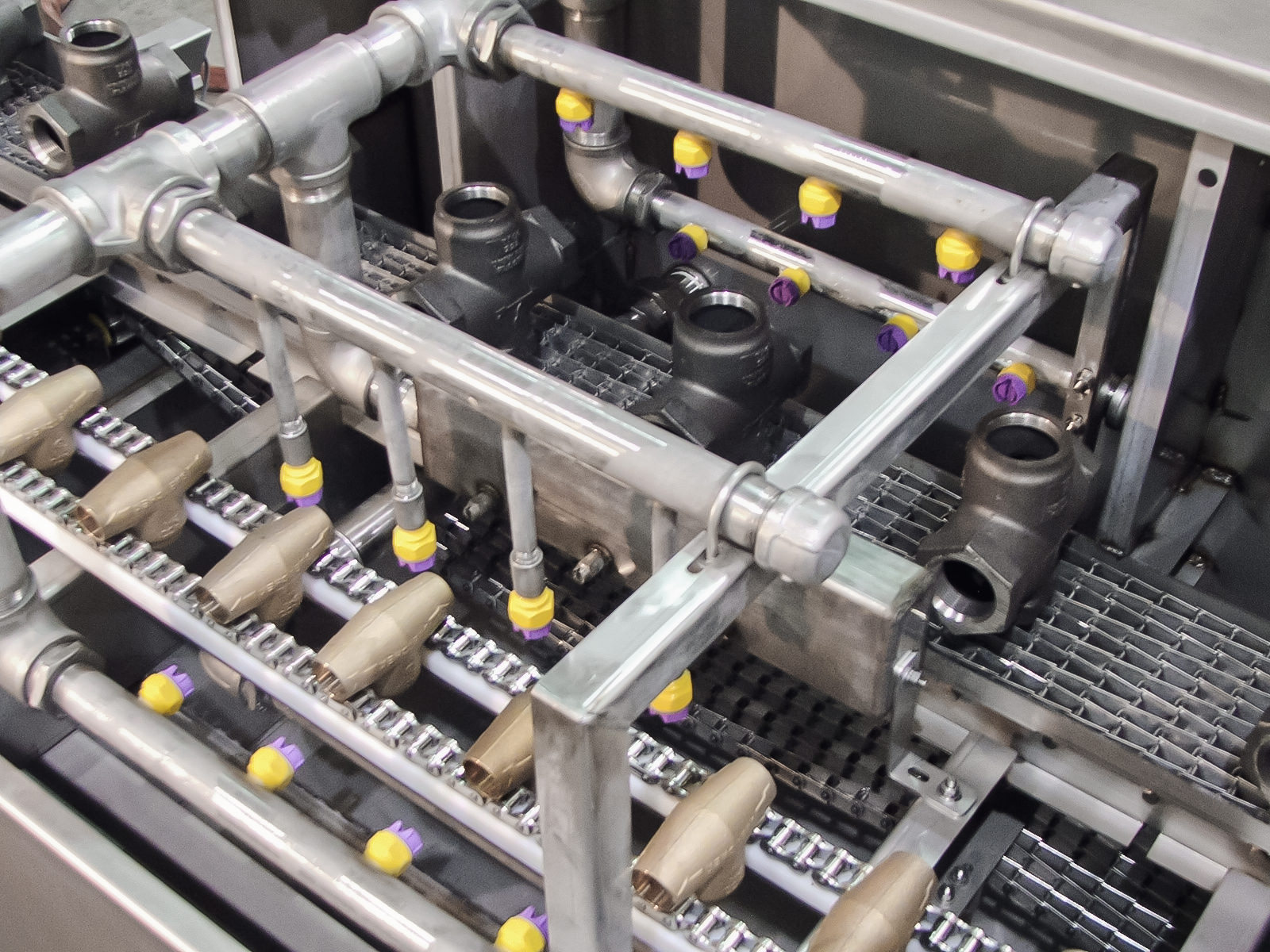

The customer required a conveyorized system to clean and dry a variety of items within two specified component groups. The machine must maintain segregation of the two groups throughout the process and allow parts to accumulate on the unload conveyor.

Solution

Alliance provided an Aquamaster CB-1800E conveyorized parts cleaning system with wash and heated blowoff modules. Machine utilized a specially-engineered dual conveyor system for maintaining segregation of the two groups throughout the cleaning and drying process. Each conveyor was equipped with custom product guides designed for optimal transfer of the respective component groups, and included a part accumulator on the exit.