Customer Background

Customer is a major North American Tier 1 supplier of machined cast aluminum components and sub-assemblies to the automotive industry.

Challenge

The customer required an inline conveyorized cleaning system for cleaning machined cast aluminum V-6 front engine covers at a rate of 75 per hour. Additionally, parts needed to exit the machine as close to 100% dry as possible without utilizing a heated blowoff.

Solution

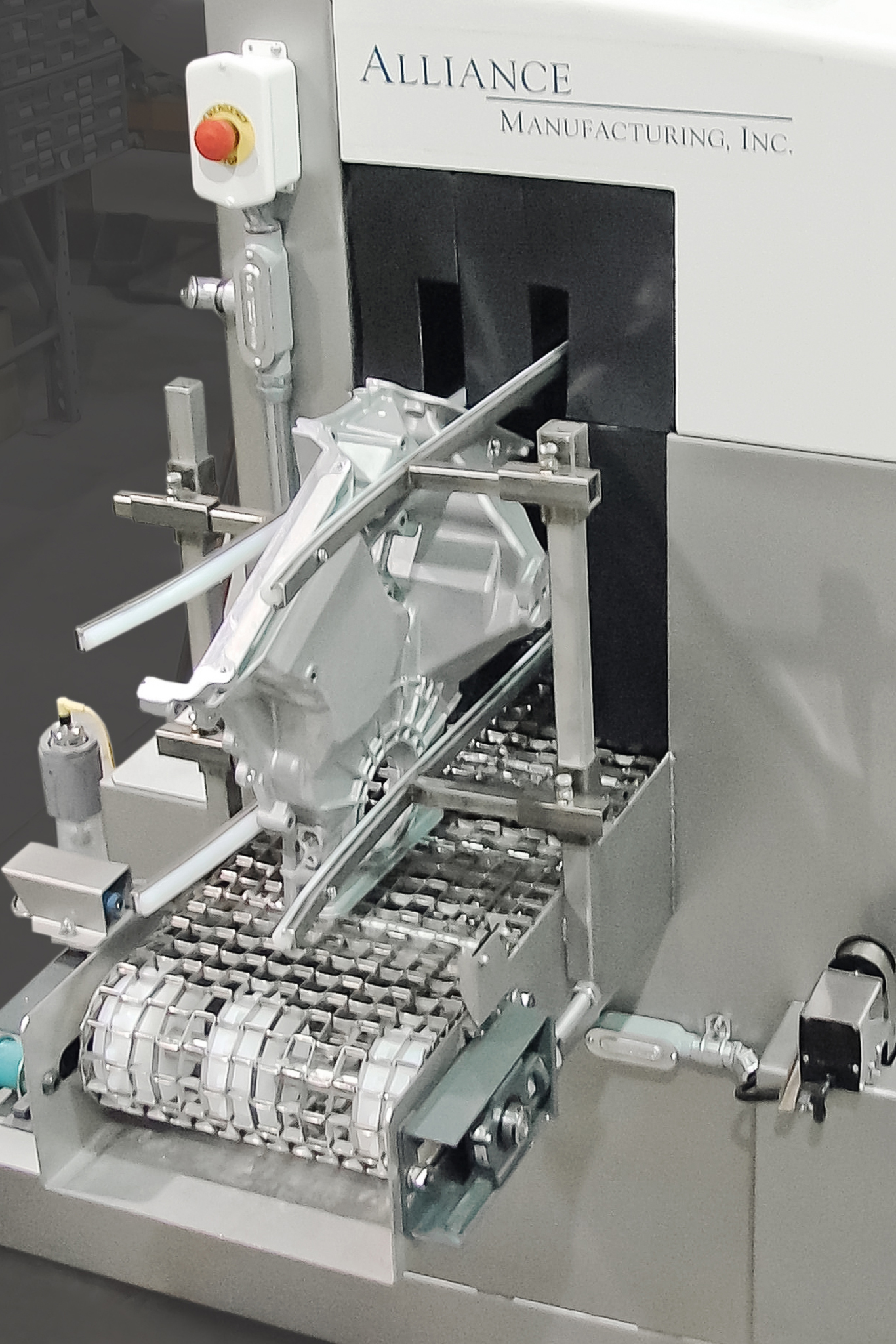

Alliance provided an Aquamaster CB-1200E conveyorized parts cleaning system with wash, rinse, and ambient blowoff modules and a 12” wide x 20” high product opening. The system utilized special product guides engineered to orient parts in a manner that minimizes carryover of moisture between stages and optimizes drying. An extended unload conveyor, equipped with a sensor to automatically stop the conveyor to prevent parts from falling when not promptly unloaded, was also utilized.