Customer Background

The customer is a large manufacturer of vehicles for the defense industry. They produce light, medium, and heavy duty vehicles, all-terrain vehicles, and more.

Challenge

The customer needed to clean various steel parts received from overseas. The parts were covered in a protective inhibitor for shipping and storage. The parts would be washed in batches, with a low-volume/intermittent production rate. Parts needed to be visually clean and completely dry upon exit.

Solution

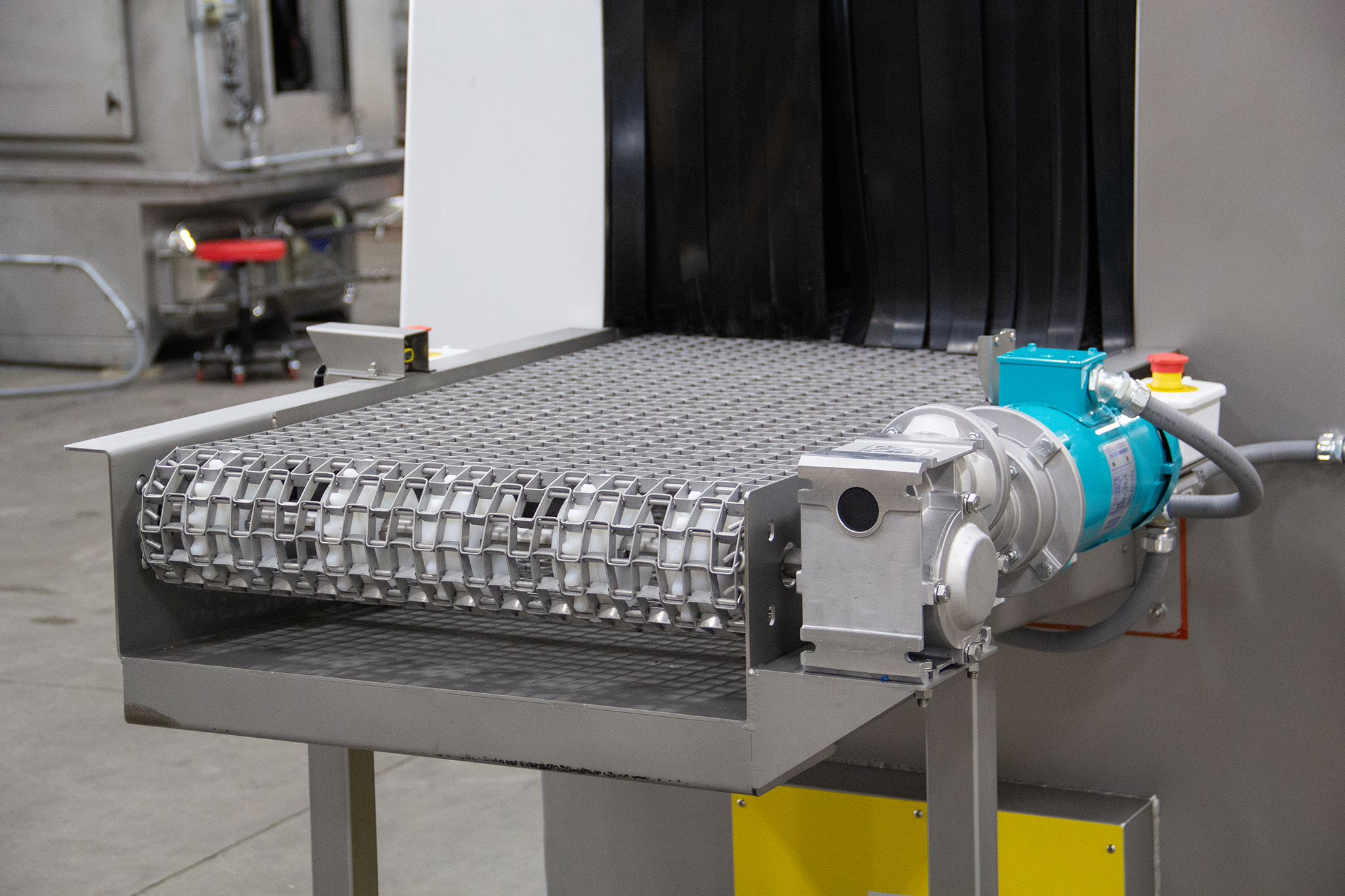

Alliance designed a belt-style parts washer with wash, rinse (rust inhibitive) and heated blow-off zones. Because the parts varied in size and weight, a 24-inch wide heavy duty conveyor belt with a direct-drive gearmotor was used. External filter chambers were included to preserve the wash and rinse solution and remove small particulate contamination, as well as an oil skimmer to remove floating oils.