Customer Background

The customer is a sport optics company that manufactures devices such as binoculars, spotting scopes, riflescopes, monoculars, tripods, and other accessories. Products are used in the industries of outdoor sports, wildlife watching, and some for law enforcement use.

Challenge

The customer was seeking a parts washer system for various aluminum and stainless steel rifle scope parts, which were contaminated with cutting oils, coolant, dirt, and dust from the manufacturing process. The parts were desired to exit the washer spot-free.

Solution

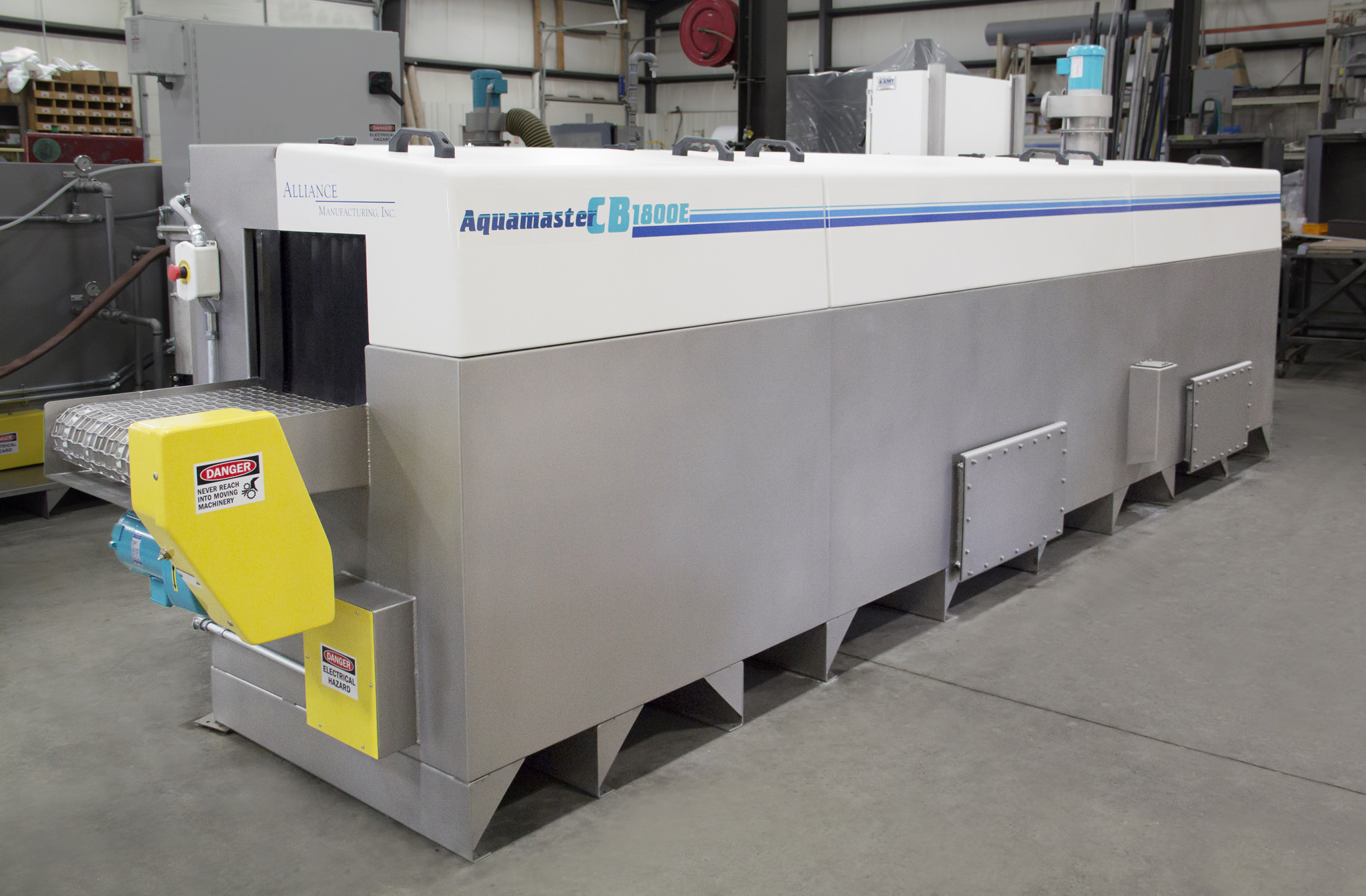

Alliance Manufacturing provided an Aquamaster CB-1600E conveyor belt parts washer with wash, rinse, triple rinse, and heated blowoff modules. In order to achieve a spot-free clean finish, an optional triple-rinse feature for use with deionized water was incorporated. The triple rinse system is designed to maximize the benefit of the deionized water, which can be costly when running on a continuous basis. A stainless steel adjustable-speed conveyor belt was provided for varying production rates. A thermostatically controlled heated blowoff system with air knives above and below the conveyor evaporates moisture from cleaned parts. An optional photo eye sensor at the load end senses parts and turns on the pumps and blowers in sequence, which saves on energy consumption when the machine is not in use.