Customer Background

Designer and manufacturer of electric motors, mechanical power transmission products, drives, and generators. Company has plants in the U.S., Canada, England, Mexico, and China. They sell their products to distributors and original equipment manufacturers.

Challenge

Customer was seeking a washer to clean various housing fixtures at a rate of 20 or fewer parts per hour. They needed chips removed from drilled and tapped holes and counter bores. Cleaned parts need to meet a cleanliness specification.

Solution

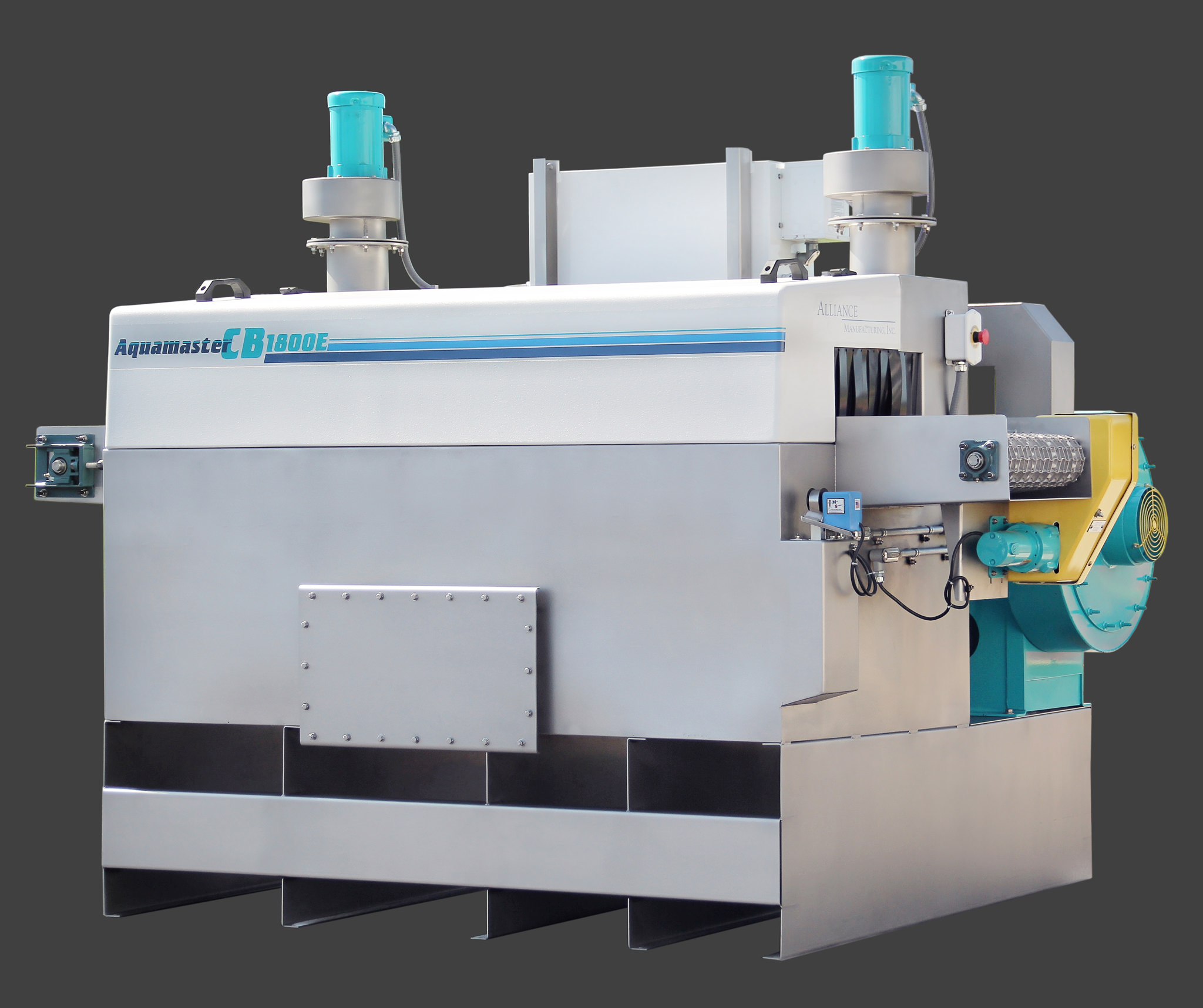

Alliance provided an Aquamaster CB-1800E conveyorized parts cleaning system with wash and ambient blowoff modules. A heavy-duty conveyor was incorporated for increased load capacity. Spray nozzles positioned on the top, bottom, and sides of the conveyor provide 360° spray coverage. Five high-velocity air knives surround the conveyor in the blowoff module and strip residual moisture from parts. Optional accessories included were an exhaust fan system, a belt-type oil skimmer, and a photo eye sensor. The photo eye positioned at the load end of the machine is used to conserve energy. The pumps, blowers, and other devices can be turned on in sequence when parts are loaded onto the conveyor and break the path of the photo eye.