Customer Background

A full-service, globally recognized stamping firm specializing in deep draw, progressive, and fine blanked components, serving automotive, industrial, consumer, electrical, and home hardware markets.

Challenge

Producing high volumes of precision metal components requires consistent cleaning of parts prior to finishing or assembly. Manual or inconsistent stamping oil cleaning methods can slow production, increase labor costs, and risk quality issues.

Solution

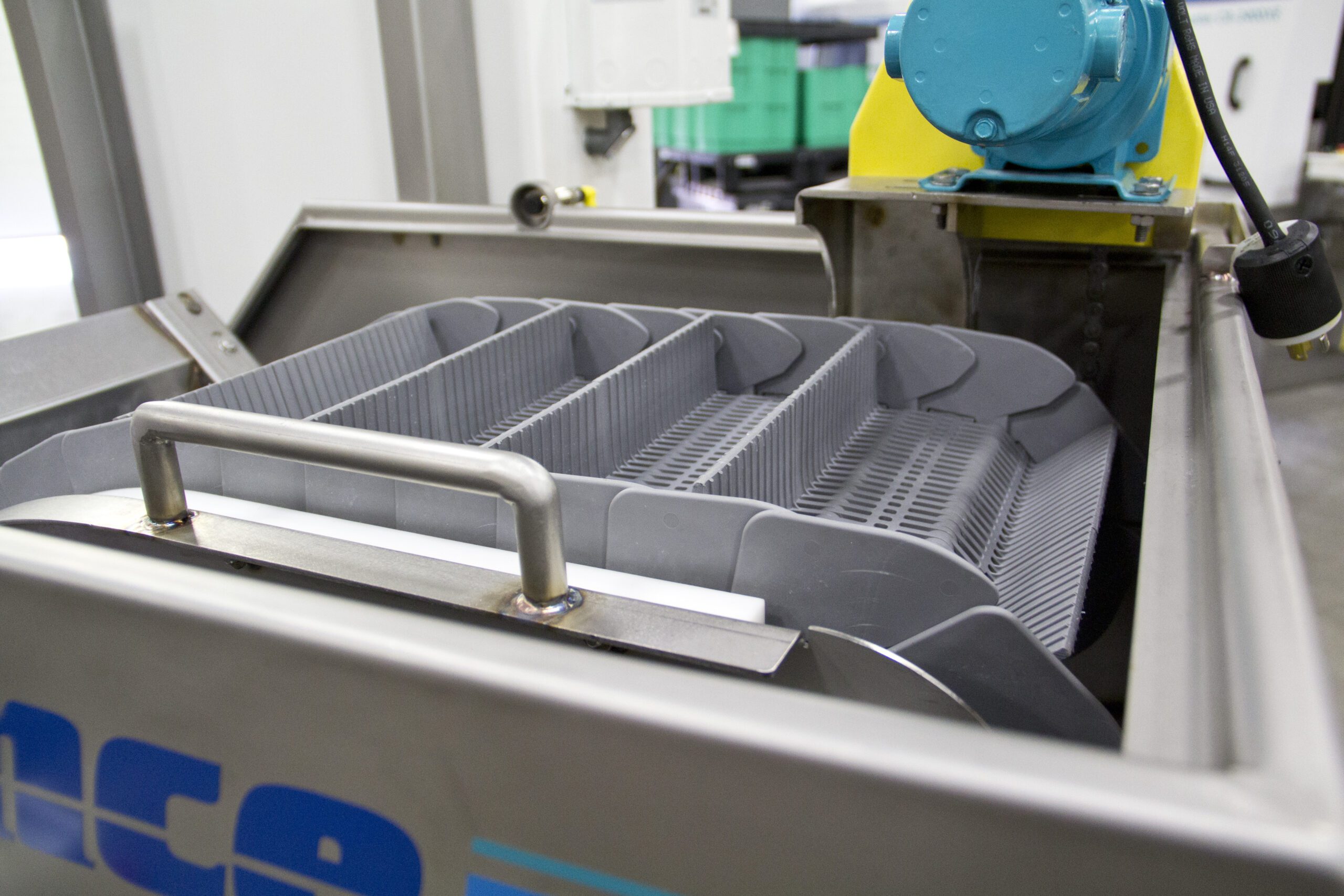

The conveyorized dip wash system streamlines the stamping oil cleaning process, reduces labor, improves throughput, and maintains high-quality standards, supporting the company’s high-volume, automated production processes. A Conveyorized dip parts cleaning system.

Cleaning Method

Aqueous cleaning was ideal for this application because the stampings are small in profile and require general spraying to remove the contaminants.