Customer Background

A global manufacturer of advanced optical lenses and coatings serving the ophthalmic eyewear industry, focused on high-quality, high-volume precision production.

Challenge

Remove fine residues and chemicals from delicate optical lenses without damage, while meeting strict cleanliness and dryness standards at production speed. Cleaning Optical Lenses safely and too strict standards.

Solution

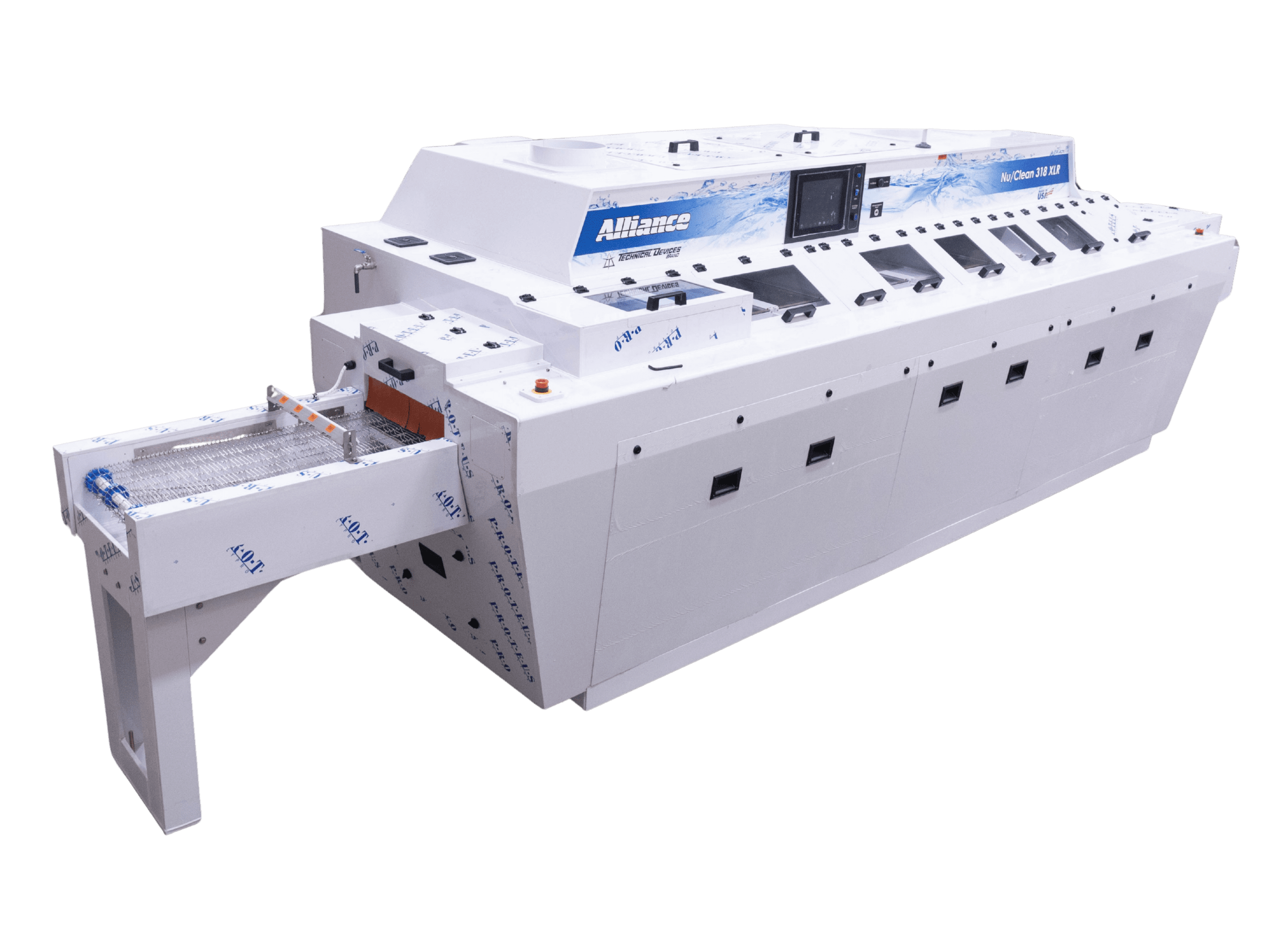

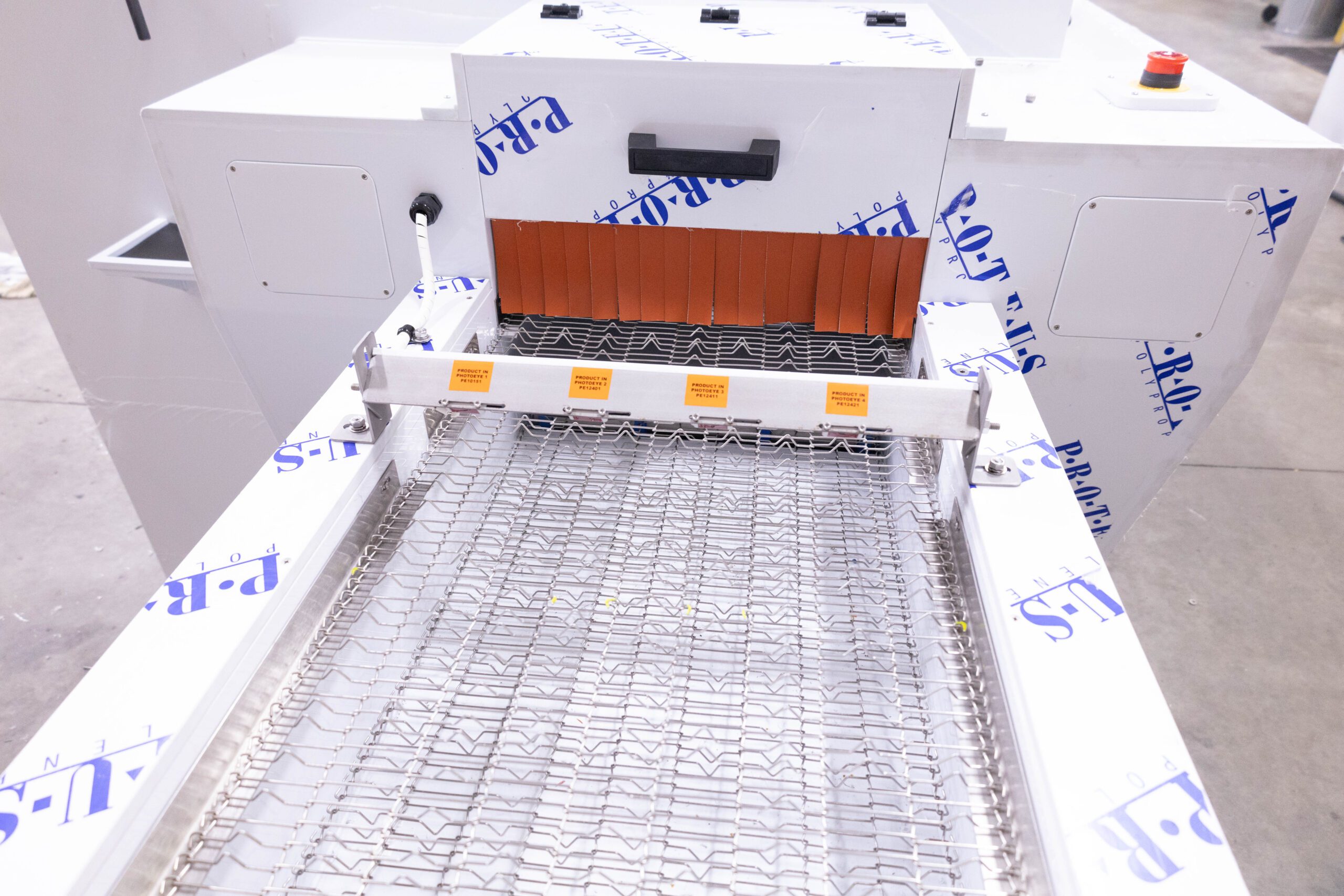

Nu/Clean™ 318 XLR inline aqueous cleaning system with multi-stage wash, rinse, isolation, and advanced drying, configured with special belt pockets and radiant convected drying.

Cleaning Method

Inline multi-stage aqueous spray cleaning with heated wash, isolation rinse, recirculating rinse, final DI rinse, followed by high-efficiency air knife and IR tunnel drying.