How Collaboration Helped New Method Plating Meet TURA Requirements

Transitioning away from legacy chemistries is rarely simple, especially in a production plating environment where quality, throughput, and reliability are non‑negotiable. In a recent webinar hosted in collaboration with the Toxics Use Reduction Institute (TURI), Nicholas Capalbo, Co‑President of New Method Plating Co. in Worcester, Massachusetts, shared the company’s multi‑year journey to eliminate trichloroethylene and adopt a safer, high‑performance TCE alternative.

This project is a strong example of what’s possible when manufacturers, technical institutes, and equipment partners work together with a clear goal: reducing risk without sacrificing results.

👉 Watch the full webinar here.

A Legacy Operation Facing Modern Challenges

From the outset, Alliance Manufacturing worked closely with New Method Plating to understand not just the regulatory drivers behind this project, but the operational realities of a high‑mix, production plating environment.

Founded in 1931, New Method Plating is a third‑generation, family‑owned business specializing in zinc, cadmium, and nickel plating. Like many plating shops, the company relied on TCE vapor degreasing for decades because it worked—and worked well.

But aging equipment, rising maintenance demands, increasing waste‑handling costs, and the looming regulatory pressure around TCE made one thing clear: continuing with the status quo was no longer sustainable.

“We knew we needed to address it,” Capalbo explained, “but switching away from something that has always delivered consistent results is not an easy decision.”

The Role of Collaboration and TURI Guidance

Alliance Manufacturing served as a technical and implementation partner throughout the evaluation process, helping bridge the gap between TURI’s safer‑chemistry guidance and the practical demands of daily production.

This transition wasn’t driven by a single vendor or a one‑size‑fits‑all recommendation. Instead, it was shaped through close collaboration between:

- New Method Plating, defining real‑world production needs and constraints

- TURI, providing technical insight, testing support, and guidance on safer trichloroethylene alternatives

- Alliance Manufacturing, helping identify and implement equipment capable of meeting both performance expectations and TURA (Toxics Use Reduction Act) requirements.

Through testing, solvent trials, and equipment evaluations, the group worked together to ensure the selected solution would handle New Method’s wide range of incoming parts, soils, and oils—critical for a true job shop environment.

Selecting Equipment That Met the Requirements

With a clear understanding of TURA’s requirements and New Method Plating’s production goals, Alliance Manufacturing helped guide equipment evaluation, supplier coordination, and system configuration to ensure long‑term success.

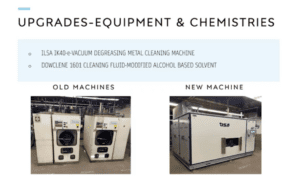

After extensive evaluation, New Method Plating replaced two aging degreasers with a single ILSA IK‑40E vacuum degreasing system, paired with a modified alcohol solvent (Dowclene 1601).

Key factors in the decision included:

- Compatibility with multiple metals (steel, stainless, aluminum, brass, die cast)

- Effective removal of heavy and unknown machining oils

- Fully enclosed vacuum operation

- Solvent recovery and recycling within the system

- Customization to fit existing floor space and basket configurations

Alliance Manufacturing played a key role in aligning the equipment configuration with New Method’s production realities—down to modifying machine height and adapting the chamber to accept existing baskets.

Measurable Results: Safety, Cost, and Performance

Because the solution was properly matched to the application from the start—a core focus of Alliance Manufacturing’s approach—the results were immediate and measurable.

Since startup, the results have exceeded expectations:

- Complete elimination of TCE from operations

- Significant reduction in hazardous waste costs, including a shift from hazardous solvent waste to non‑hazardous oil disposal

- Improved part cleanliness, with customers noting cleaner, shinier finishes—especially on stainless steel

- Lower energy consumption, replacing two machines and a high‑pressure steam boiler with one automated system

- Consistent, repeatable cleaning, driven by automated cycle controls rather than fixed time settings

Perhaps most telling: customer feedback was overwhelmingly positive, even without advance notice of the chemistry change.

A Practical Path Forward for Platers

This project reinforces Alliance Manufacturing’s belief that successful transitions away from legacy solvents like TCE depend on collaboration, application‑specific equipment selection, and upfront testing.

New Method Plating’s experience underscores an important lesson: moving away from TCE doesn’t have to mean compromising productivity or quality. With the right partners, proper testing, and equipment designed for modern solvents, shops can meet environmental goals and improve operations at the same time.

As Capalbo emphasized during the webinar, the key is to start early, ask questions, and lean on available resources like TURI and experienced equipment partners.

👉 Watch the full webinar here

If you’re evaluating alternatives to TCE or exploring equipment that aligns with TURA’s requirements, collaboration makes all the difference—and this project is proof of that.

At Alliance Manufacturing, our mission is to help manufacturers transition to safer, more sustainable cleaning technologies—without compromising performance, quality, or productivity. Through close collaboration with our customers and technical partners, we work to identify equipment solutions that meet regulatory expectations while supporting real‑world production demands.

Ready to Explore a Safer Cleaning Solution?

If you’re evaluating alternatives to TCE or need equipment that aligns with TURA’s requirements while maintaining production performance, Alliance Manufacturing can help.

Our team works directly with manufacturers to assess applications, recommend properly sized systems, and support implementation from evaluation through startup.

👉 Request a quote to start a conversation about safer, more efficient parts cleaning solutions tailored to your operation.

🌐 Visit: alliancemfginc.com